- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

2026 Top Die Casting Molds What You Need to Know?

Die Casting Molds are essential in manufacturing. They create precise metal parts used in various industries. Understanding these molds is crucial for companies looking to enhance production quality.

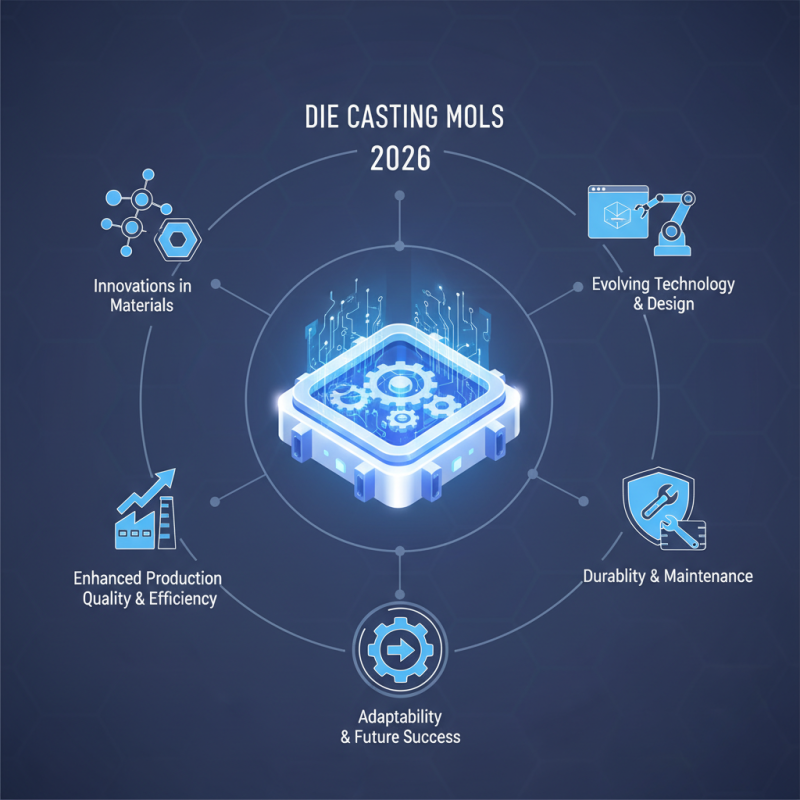

In 2026, the landscape of die casting molds will evolve. Innovations in materials and technology will influence design and efficiency. Companies must adapt to these changes to stay competitive. The importance of choosing the right mold cannot be overstated.

However, not all molds are perfect. Some may wear down faster than anticipated. This can lead to increased maintenance costs. It’s vital to assess the longevity and performance of chosen die casting molds carefully. In this dynamic industry, reflection and adaptability are key to success.

Overview of Die Casting Molds in 2026

Die casting molds are crucial in shaping metal products efficiently. In 2026, their role continues to evolve. These molds allow for high precision and complex designs. With advancements in technology, they are becoming more durable and cost-effective. Manufacturers are focusing on materials that resist wear and tear. This enhances the lifecycle of the molds.

However, challenges persist. The production process is sometimes slow, and quality control can be tricky. Unforeseen defects may arise, leading to costly reworks. Companies are investing in better monitoring techniques. Data-driven approaches help in predicting potential failures. Not all manufacturers have embraced this shift, which raises concerns about competitiveness.

As the industry matures, flexibility in design becomes more important. Custom molds can cater to specific needs. Yet, this requires a skilled workforce that can adapt. Not every organization has the training programs in place. Reflecting on these issues is crucial for future progress. The landscape of die casting molds in 2026 is a mix of promise and challenges.

2026 Top Die Casting Molds Overview

Key Materials Used in Die Casting Molds

Die casting molds are essential in manufacturing. They create precise parts for various industries. The choice of materials for molds significantly affects their performance and longevity. The most common materials include steel, aluminum, and copper. Each material has its own unique properties that cater to different casting needs.

Statistics show that steel is the most used material for die casting molds. It accounts for about 70% of the market. Steel molds resist wear and provide long life cycles. They are ideal for high-volume production. However, they can be costly. Many manufacturers opt for aluminum molds for their balance of performance and cost. Aluminum molds excel in lower production runs and complex shapes. They are lighter and easier to work with.

In the future, advancements in materials science may change the landscape. Innovative composites might offer new possibilities. However, the industry still struggles with high initial costs and limited mold lifespan. It requires careful consideration. Effective mold design is also critical. Factors like draft angles and wall thickness need attention. Failing to optimize these can lead to defects. Thus, choosing the right material is pivotal for success.

Factors Affecting Die Casting Mold Design

Die casting mold design depends on several factors that can impact efficiency and quality. Material selection plays a significant role. Many companies prefer aluminum and zinc due to their lightweight and durability. According to a recent industry report, aluminum die casting can increase production rates by 20%.

Design complexity is another factor. Intricate designs often require advanced mold techniques. The number of cavities within a mold can also affect productivity. More cavities can mean faster production, but this can lead to potential quality issues if not managed correctly.

Tips: Consider your cooling system design. Efficient cooling can enhance cycle times. Regularly review your design for any possible simplifications. This can help avoid unnecessary complications. Material flow is crucial too. Ensure that the mold allows for optimal flow to reduce defects.

2026 Top Die Casting Molds - Factors Affecting Die Casting Mold Design

| Factor | Description | Impact on Design | Considerations |

|---|---|---|---|

| Material Selection | Choosing the right alloy for the casting process. | Influences durability and mechanical properties. | Cost, availability, and application requirements. |

| Mold Design | The geometry and layout of the mold. | Affects casting quality and production efficiency. | Complexity, cooling channels, and draft angles. |

| Cooling System | Method used to cool the mold after casting. | Determines cycle time and surface finish. | Design, placement, and flow rate of coolant. |

| Machining Accuracy | Precision in mold manufacturing. | Impacts dimensional tolerance of parts. | Manufacturing processes and technology used. |

| Surface Treatment | Treatments applied to the mold surface. | Affects mold life and finish of cast parts. | Type of treatment and thickness considerations. |

Advancements in Die Casting Technologies for 2026

Die casting technology is evolving rapidly. As we approach 2026, several advancements stand out. These improvements focus on efficiency, precision, and sustainability. New materials are being tested, allowing for lighter and stronger molds. This shift can lead to cost reductions and improved product quality.

One notable change is the adoption of smart manufacturing practices. Automation is becoming central in die casting processes. Robots are now handling intricate tasks, which boosts productivity. However, it raises concerns about workforce displacement. Finding the balance between technology and employment will require careful thought.

Moreover, sustainability is a priority. Efforts to reduce waste and energy consumption can significantly impact the industry. While these practices are promising, they also demand ongoing evaluation. Achieving an eco-friendly approach may involve trial and error. It’s essential to reflect on these challenges as the industry progresses.

Best Practices for Maintaining Die Casting Molds

Maintaining die casting molds is crucial for ensuring optimal performance and longevity. According to a recent industry report, nearly 75% of mold failures stem from improper maintenance practices. Regular inspection is essential. Check for any surface wear or corrosion. These issues can lead to greater defects and increased costs.

Ensuring proper lubrication is another key practice. The right lubricant can reduce friction and extend mold life. However, using incorrect lubricants can be detrimental. Many in the industry forget this detail, compromising mold efficiency. Visual inspections and cleaning after each use can prevent expensive repairs.

Incorporating advanced monitoring technologies can improve upkeep. Sensors can detect temperature fluctuations and pressure discrepancies. This data allows for timely interventions. However, implementation costs can deter some smaller operations. Not every facility has the resources for such upgrades. Maintaining a proactive approach remains vital, yet many still react only when problems arise. Invest time in these practices to avoid costly delays.