- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

Unlocking Efficiency: The Advantages of Choosing the Best Gear Pumps for Your Business

In today's competitive industrial landscape, the efficiency of fluid handling systems can significantly impact overall productivity and operational costs.

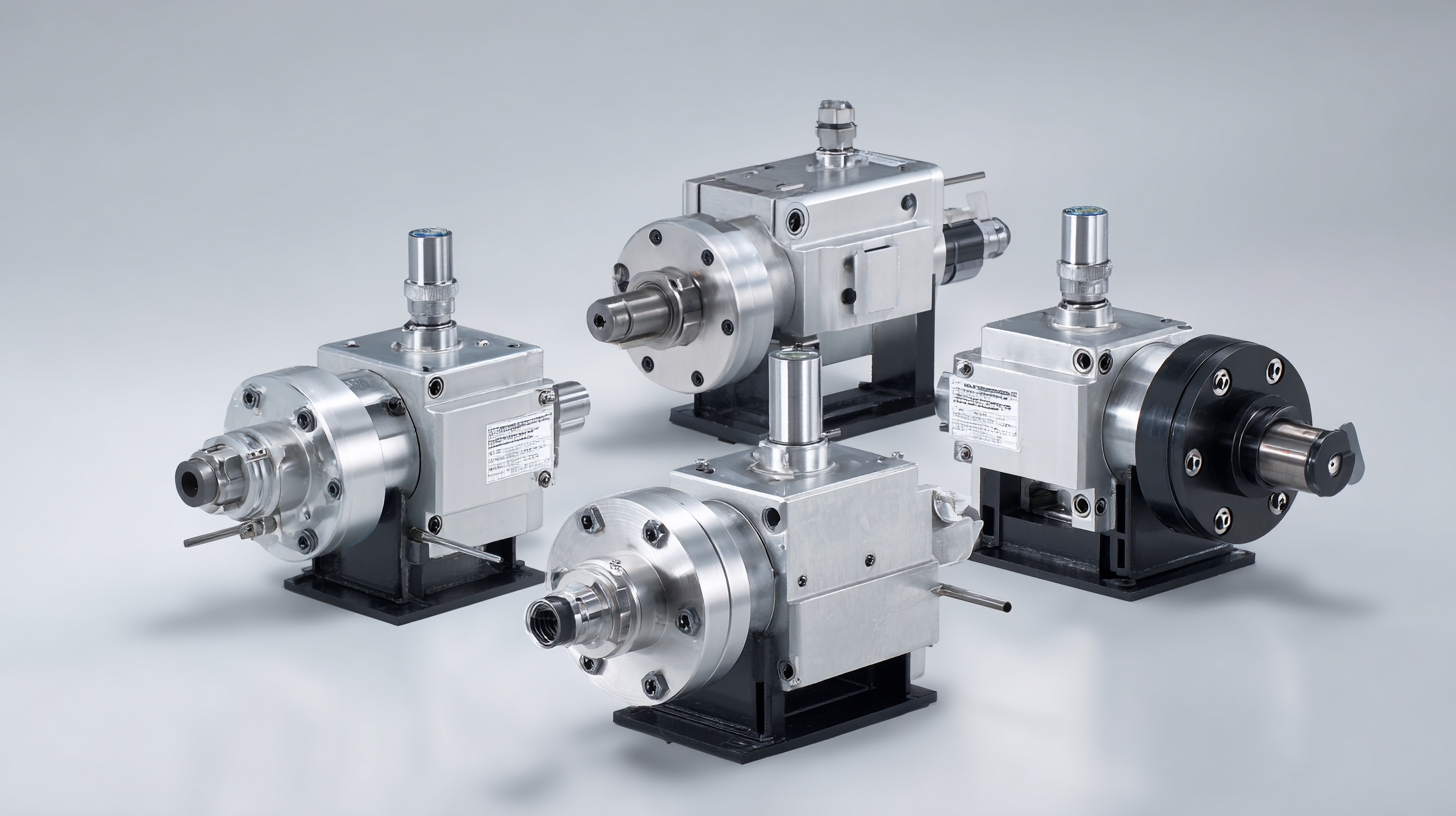

Gear pumps, known for their reliability and performance, are gaining traction among industries requiring precise fluid transfer solutions.

According to a report by MarketsandMarkets, the global gear pump market is projected to reach USD 3.5 billion by 2025, growing at a CAGR of 4.2%. This surge highlights the increasing recognition of gear pumps not only for their high efficiency and low maintenance requirements but also for their adaptability across various applications, including chemical processing, food and beverage, and oil and gas.

By investing in the best gear pumps, businesses can streamline operations, reduce downtime, and ultimately achieve a significant return on investment. Understanding the advantages these pumps offer is essential for companies looking to unlock their full potential and drive sustainable growth.

Gear pumps, known for their reliability and performance, are gaining traction among industries requiring precise fluid transfer solutions.

According to a report by MarketsandMarkets, the global gear pump market is projected to reach USD 3.5 billion by 2025, growing at a CAGR of 4.2%. This surge highlights the increasing recognition of gear pumps not only for their high efficiency and low maintenance requirements but also for their adaptability across various applications, including chemical processing, food and beverage, and oil and gas.

By investing in the best gear pumps, businesses can streamline operations, reduce downtime, and ultimately achieve a significant return on investment. Understanding the advantages these pumps offer is essential for companies looking to unlock their full potential and drive sustainable growth.

Identifying Your Business Needs: Why Gear Pumps Matter

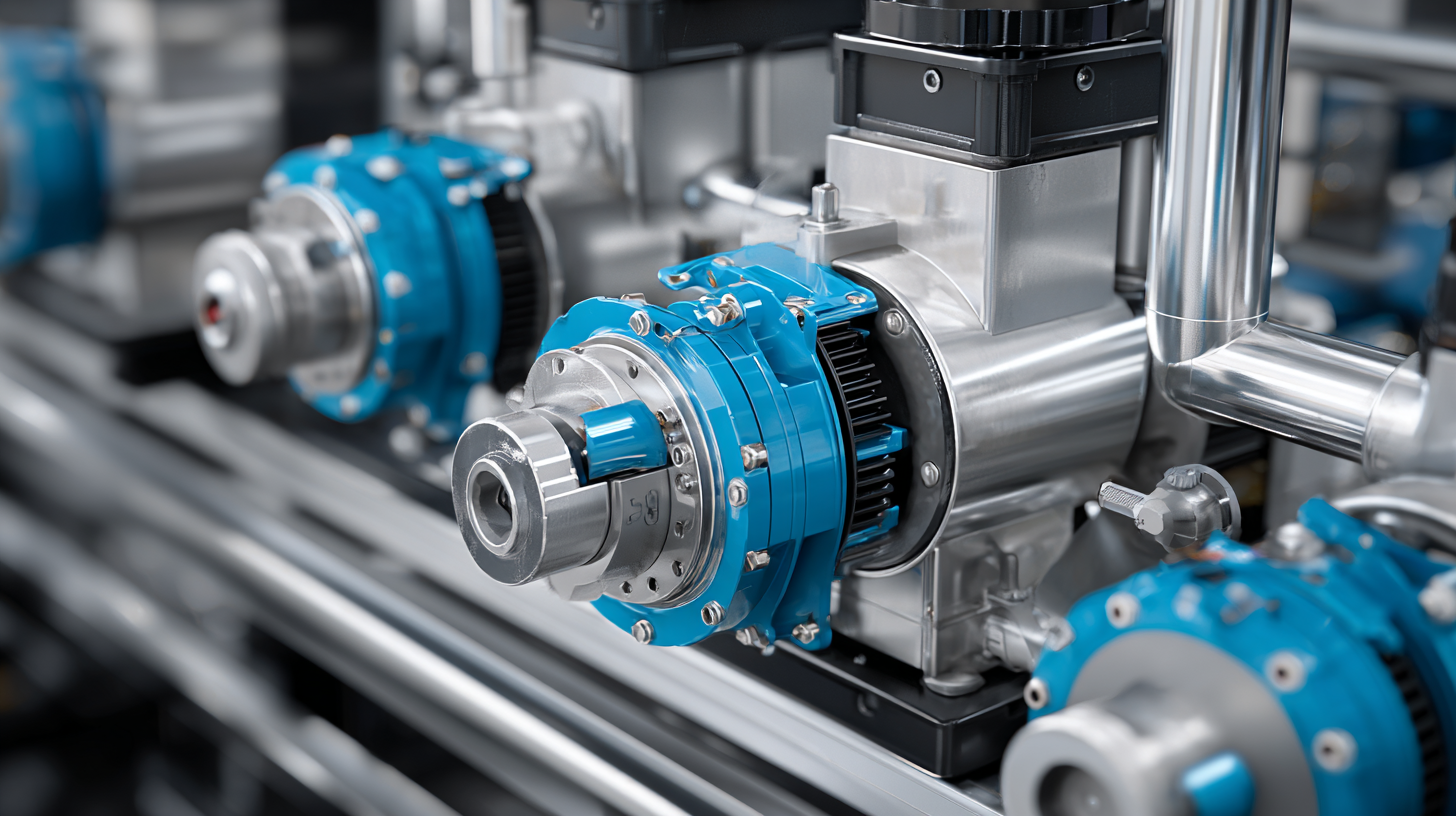

When evaluating the importance of gear pumps for your business, it’s crucial to first identify your specific operational needs. Gear pumps are designed to provide consistent flow rates, making them ideal for applications that demand precision and reliability. According to industry reports, the demand for gear pumps is projected to grow at a CAGR of 6.3% through 2026, indicating their pivotal role in various sectors, including manufacturing and processing. Selecting the right gear pump can significantly impact operational efficiency, particularly in environments prone to severe weather where consistent performance is critical.

Furthermore, understanding the gear pump technology is essential, especially as manufacturers work to enhance pump efficiency. As noted, modern designs have improved both flow and pressure capabilities, allowing businesses to tackle challenges related to material handling effectively. Companies that integrate advanced gear pump solutions are better positioned to address labor shortages and reduce operational bottlenecks. By aligning gear pump specifications with business requirements, companies can not only streamline their processes but also leverage robust data insights to make informed purchasing decisions.

Evaluating Gear Pump Performance: Key Features to Consider

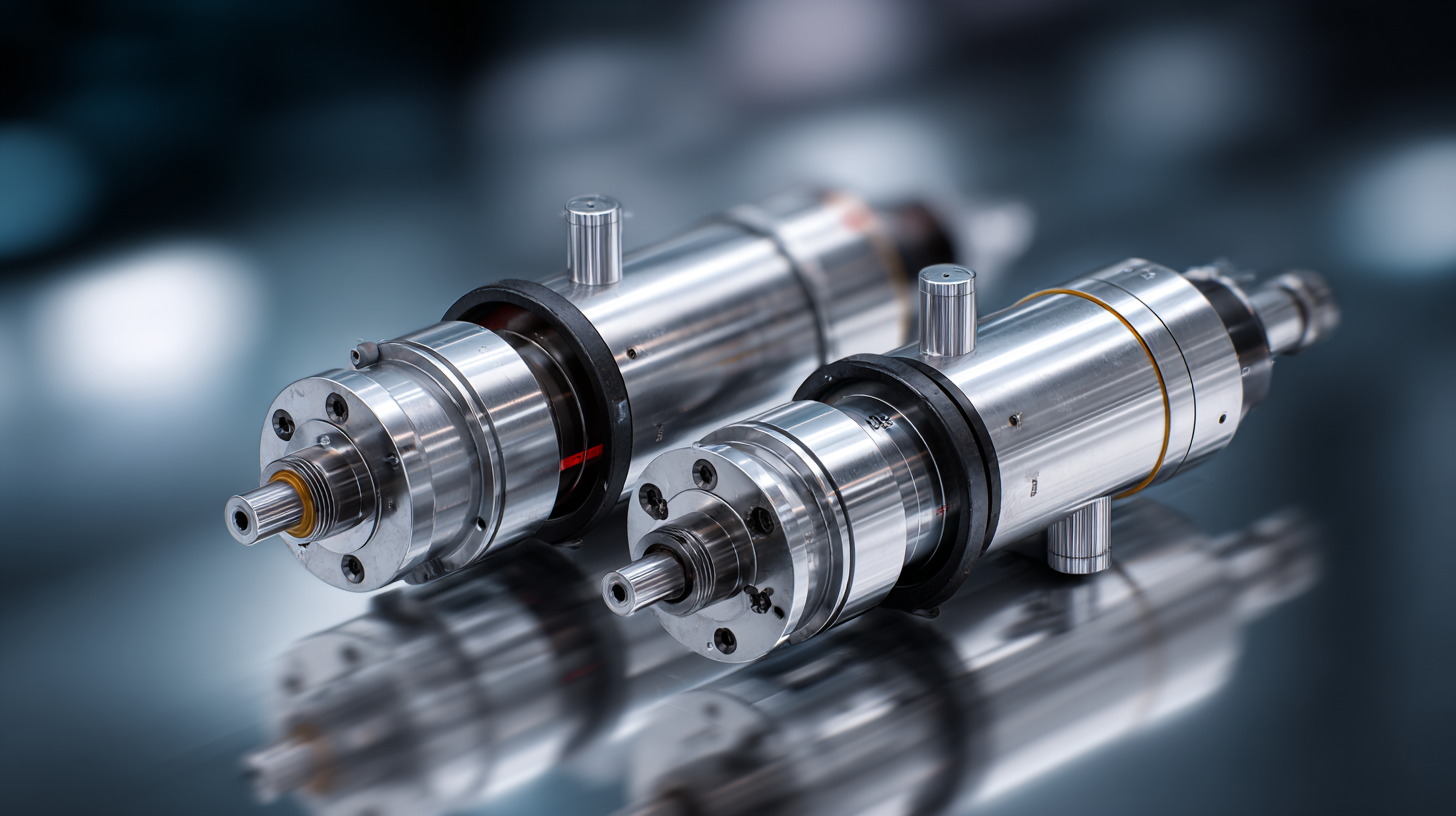

When evaluating gear pump performance, several key features should be at the forefront of your decision-making process. First and foremost is the pump's efficiency. High-efficiency gear pumps can effectively minimize energy consumption while maintaining optimal flow rates. Look for models that demonstrate a low slip rate, as this can significantly impact the overall efficiency of the pumping system. Additionally, pressure ratings are crucial; select pumps that can handle the specified pressure for your application to ensure reliability and longevity.

Another important factor is the material construction of the gear pump. Depending on the fluids you intend to pump, the material should resist corrosion and wear. For example, stainless steel pumps are excellent for abrasive or corrosive liquids, while cast iron might be suitable for less aggressive applications. Moreover, consider the ease of maintenance. Pumps designed for easy disassembly and cleaning can save valuable downtime, enhancing your workflow and operational efficiency. Ultimately, a thorough evaluation of these features will help you choose the best gear pump tailored to your business needs.

Cost vs. Quality: Balancing Your Budget with Best Gear Pumps

When selecting gear pumps for your business, a critical consideration is balancing cost with quality. Research indicates that investing in high-quality gear pumps can lead to significant long-term savings. According to a report by MarketsandMarkets, the global gear pump market is projected to reach USD 2.3 billion by 2025, underscoring the demand for reliable and efficient pumping solutions.

Businesses that opt for lower-cost alternatives often face increased maintenance and operational costs, which can exceed initial savings.

Moreover, quality gear pumps typically offer enhanced efficiency, reducing energy consumption during operation. The Hydraulic Institute noted that using high-efficiency pumps can result in energy savings of up to 30%, translating to lower operational costs over time.

As industries strive to meet sustainability targets, choosing the best gear pumps not only supports cost management but also aligns with broader environmental goals. Investing wisely can ultimately contribute to an improved bottom line and operational reliability, solidifying your position in a competitive market.

Maintenance Tips: Ensuring Longevity of Your Gear Pumps

When it comes to maximizing the longevity and efficiency of gear pumps, regular maintenance is crucial. According to a report by the Hydraulic Institute, proper maintenance can extend the lifespan of gear pumps by up to 30%. This underscores the importance of adhering to a rigorous maintenance schedule, which should include routine inspections, lubrication, and timely replacement of worn components. Regularly checking for leaks and ensuring that pumps are operating within their designed pressure and temperature limits can significantly reduce the risk of unexpected failures.

Moreover, a study published in the Journal of Fluid Engineering highlights that over 70% of gear pump failures are attributed to inadequate maintenance practices. Implementing predictive maintenance techniques, such as vibration analysis and thermography, can identify potential issues before they escalate. This proactive approach not only minimizes downtime but also enhances overall operational efficiency. By investing in quality gear pumps and committing to regular maintenance practices, businesses can ensure optimal performance and extend the life of their equipment, ultimately leading to increased profitability.

Real-World Applications: Success Stories of Efficient Gear Pump Use

In today’s fast-paced industrial landscape, the choice of gear pumps is crucial for optimizing operational efficiency. Real-world applications showcase how businesses across various sectors are leveraging advanced gear pump technology to achieve remarkable results. A report by the Hydraulic Institute reveals that businesses employing high-efficiency gear pumps can reduce their energy consumption by up to 20%, translating into significant cost savings and improved sustainability.

Consider the case of a leading manufacturer in the food processing industry that switched to high-performance gear pumps. By implementing these pumps, the company reported a 35% increase in throughput while maintaining product quality. This case not only highlights the operational benefits of gear pumps but also aligns with the findings from a McKinsey report, which suggests that process optimization through better equipment can lead to productivity improvements of 10-30% in manufacturing environments. The success stories underscore the importance of selecting the right gear pumps, enhancing both operational agility and competitiveness in the market.

Unlocking Efficiency: The Advantages of Choosing the Best Gear Pumps for Your Business

| Application Industry | Gear Pump Type | Efficiency Gain (%) | Key Benefits | Success Story Highlights |

|---|---|---|---|---|

| Chemical Processing | Positive Displacement Gear Pump | 20% | Stable flow, reduced downtime | Reduced wastage, improved batch consistency |

| Food & Beverage | Sanitary Gear Pump | 15% | Hygienic design, easy cleaning | Enhanced product quality, shorter cleaning cycles |

| Oil & Gas | High-Pressure Gear Pump | 25% | Handles viscous fluids, reliable performance | Increased throughput, reduced maintenance costs |

| Pharmaceuticals | Dynamic Gear Pump | 18% | Accurate dosing, minimal shear | Improved yield, compliance with regulations |