- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

Unlocking the Advantages of Hydraulic Pumps for Enhanced Operational Efficiency

In today's rapidly evolving industrial landscape, the efficiency and effectiveness of operations are paramount for maintaining competitive advantage. Hydraulic pumps, a cornerstone of modern machinery, play a pivotal role in enhancing operational efficiency across various sectors, including manufacturing, construction, and agriculture. According to a recent industry report by ResearchAndMarkets, the global hydraulic pumps market is projected to reach $12 billion by 2026, with a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026. This growth underscores the increasing reliance on hydraulic systems for powering equipment and streamlining processes. By unlocking the advantages of hydraulic pumps, organizations can not only improve performance and reduce energy consumption, but also increase productivity and reliability in their operations. Understanding the multifaceted benefits of these systems is crucial for decision-makers aiming to optimize their workflows and leverage state-of-the-art technology in today's competitive environment.

Understanding Hydraulic Pumps: The Backbone of Modern Machinery

Hydraulic pumps play a pivotal role in modern machinery, serving as the backbone for a variety of industrial applications, including agricultural mechanics and hydraulic mining. In the agricultural sector, maintenance and repair of equipment heavily rely on efficient hydraulic systems to ensure optimum performance. According to a recent report by the American Society of Agricultural and Biological Engineers, hydraulic systems can improve operational efficiency by up to 30%, making them indispensable in enhancing productivity on farms.

In the realm of hydraulic mining, the technology has evolved significantly, with hydraulic pumps enabling the extraction of minerals with less environmental impact. The use of high-pressure water jets not only maximizes recovery rates but also minimizes the ecological footprint, facilitating sustainable practices in an industry that's often scrutinized for its environmental effects. As reported in the latest industry analysis, advancements in hydraulic pump technology are projected to drive a 15% increase in operational efficiency by 2025, indicating the continued importance of these systems in modern extraction techniques. By integrating cutting-edge hydraulic technologies, businesses can capitalize on enhanced performance and productivity across various sectors.

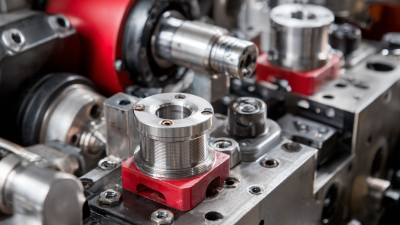

Key Advantages of Hydraulic Pumps in Industrial Applications

Hydraulic pumps are pivotal components in a wide range of industrial applications, offering numerous advantages that enhance operational efficiency. One of the primary benefits is their ability to generate high power-to-weight ratios. This characteristic allows for the operation of heavy machinery with relatively lightweight equipment, reducing energy consumption and improving overall productivity. Additionally, hydraulic systems deliver consistent power and torque across varying speeds, making them suitable for tasks that require precise control and adaptability.

Another significant advantage of hydraulic pumps is their versatility. They can be used in various applications, from construction and manufacturing to agriculture and material handling. This flexibility is bolstered by the ability to create complex motion and force, allowing industries to tackle a broad spectrum of tasks with a single system. Moreover, hydraulic systems tend to be more durable and require less maintenance compared to their pneumatic counterparts, which translates to reduced downtime and lower operational costs. In an era where efficiency and productivity are paramount, the benefits of hydraulic pumps cannot be overstated.

Top Tips for Selecting the Right Hydraulic Pump for Your Needs

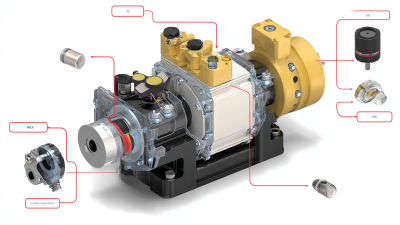

When selecting the right hydraulic pump for your needs, it's essential to consider several key factors to enhance operational efficiency. First and foremost, assess the specific application requirements. Different hydraulic systems demand varying flow rates and pressure specifications. Understanding these needs will help you narrow down the options, ensuring that the pump you choose can handle the operational loads without compromising performance.

Another crucial aspect is the type of hydraulic pump. There are several types available, including gear, vane, and piston pumps, each having distinct advantages in different scenarios. For instance, gear pumps are generally more efficient for moderate pressures and simple applications, while piston pumps excel in high-pressure environments. Additionally, consider the pump's size and compatibility with your existing system to avoid costly modifications or inefficiencies.

Lastly, don’t overlook the manufacturer’s reputation and the pump's maintenance requirements. Opting for a reliable brand with a proven track record can save you from unexpected breakdowns and prolong service life. Regular maintenance checks, tailored to the specific pump type, will further ensure optimal performance and longevity, maximizing the benefits of your hydraulic system.

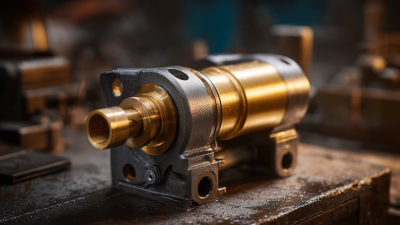

Maintaining Hydraulic Pumps for Optimal Efficiency and Longevity

Maintaining hydraulic pumps is crucial for achieving optimal efficiency and longevity in various industrial applications. According to a report by the Hydraulic Institute, regular maintenance can enhance a hydraulic pump's efficiency by up to 20%. This improvement not only reduces energy consumption but also minimizes operational costs, making it a wise investment for businesses. Key maintenance practices, such as regularly checking fluid levels and conducting thorough inspections for wear and tear, can prevent costly downtimes and extend the life of hydraulic systems.

Moreover, the same report emphasizes that a staggering 70% of hydraulic system failures are attributed to contamination in the hydraulic fluid. By implementing effective filtration systems and ensuring the fluid is free from particulate matter, organizations can significantly reduce the incidence of failure and ensure smoother operation. This not only boosts the productivity of the system but also decreases the likelihood of catastrophic failures that disrupt operations and incur heavy repair costs. Regular maintenance combined with diligent oversight can lead to sustainable operational efficiency in hydraulic systems.

Innovative Technologies in Hydraulic Pump Design and Performance

In recent years, the hydraulic pump industry has witnessed significant advancements driven by innovative technologies. According to the Hydraulic Institute's latest report, the development of variable displacement pumps has led to a 20% increase in energy efficiency in many applications. These pumps dynamically adjust their displacement to meet varying flow demands, minimizing energy consumption during low-load conditions. This technology not only enhances operational efficiency but also contributes to lower operational costs and reduced environmental impact.

Furthermore, the integration of IoT and smart sensors in hydraulic pump design plays a pivotal role in performance optimization. A study by the International Fluid Power Society indicates that smart hydraulics can improve system uptime by up to 30% through predictive maintenance and real-time monitoring. This integration allows operators to foresee potential failures, optimize maintenance schedules, and ultimately ensure continuous performance without unexpected downtimes. As industries increasingly adopt these innovative hydraulic solutions, the potential for improved efficiency and cost-effectiveness becomes more pronounced, establishing a new standard in operational excellence.

Related Posts

-

5 Best Practices for Choosing Hydraulic Pumps for Your Business

-

7 Reasons Why Best Hydraulic Pump Parts Enhance Equipment Efficiency

-

World-Class Pump Manufacturing: China's Pride in Global Exports

-

Solving Common Issues with Hydraulic Pump Motors for Global Buyers

-

Exploring the Versatility of High Pressure Pumps Across Different Industries and Their Unique Benefits

-

Exploring Innovative Alternatives to Best Piston Pump for Enhanced Efficiency and Performance