- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

Unlocking Efficiency: The Advantages of Hydraulic Valves in Modern Applications

In recent years, the demand for efficient hydraulic systems has surged across various industries, driven by the need for enhanced performance and reduced operational costs. According to a report by the International Hydraulic Association, the global hydraulic equipment market is projected to reach $53 billion by 2025, with hydraulic valves playing a pivotal role in this growth. These critical components are designed to control the flow and pressure of hydraulic fluids, ensuring precise operation in applications ranging from construction machinery to automotive systems.

By unlocking efficiency through advanced hydraulic valve technology, businesses can not only improve the reliability of their operations but also achieve significant energy savings. As industries strive to embrace automation and optimize productivity, understanding the advantages of hydraulic valves becomes essential for leveraging their full potential in modern applications.

By unlocking efficiency through advanced hydraulic valve technology, businesses can not only improve the reliability of their operations but also achieve significant energy savings. As industries strive to embrace automation and optimize productivity, understanding the advantages of hydraulic valves becomes essential for leveraging their full potential in modern applications.

Exploring the Role of Hydraulic Valves in Enhancing Machinery Efficiency

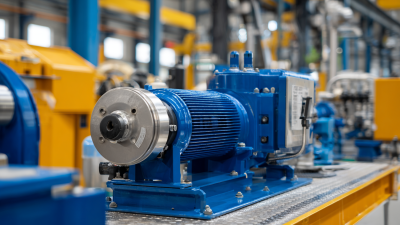

Hydraulic valves play a crucial role in optimizing the performance of various machinery across diverse industries. These components are essential for controlling the flow and direction of hydraulic fluid, enabling precise movements and functionalities in equipment ranging from construction machinery to manufacturing systems. By regulating pressure and flow, hydraulic valves enhance the efficiency of operations, allowing for smoother and more reliable performance.

In modern applications, the ability to automate and optimize processes is paramount. Hydraulic valves facilitate this by ensuring that hydraulic systems operate at their peak efficiency, minimizing energy consumption and reducing wear on machinery. Advanced designs, such as proportional and electro-hydraulic valves, offer improved response times and adaptability, allowing for real-time adjustments based on operational demands. This adaptability not only boosts productivity but also extends the lifespan of the equipment, highlighting the integral role that hydraulic valves play in enhancing machinery efficiency.

Key Benefits of Using Hydraulic Valves in Industrial Automation Processes

Hydraulic valves are pivotal in enhancing industrial automation processes, offering significant advantages that contribute to operational efficiency. According to a report by the International Society of Automation, the use of hydraulic systems can improve energy efficiency by up to 30% compared to traditional pneumatic systems. These valves facilitate precise control of fluid flow and pressure, which is essential in applications ranging from manufacturing to robotics. With their ability to handle high pressures and provide rapid response times, hydraulic valves play a crucial role in optimizing production lines.

When integrating hydraulic valves into automation systems, it is vital to select the right type for your specific application. A recent industry study highlighted that organizations that invest in high-quality hydraulic components experience 25% fewer maintenance issues. This not only reduces downtime but also prolongs the lifespan of the machinery.

Tip: Regular maintenance and inspections can greatly enhance the performance of hydraulic systems. Simple practices such as monitoring fluid levels and checking for leaks can prevent costly disruptions. Additionally, leveraging advanced predictive maintenance technologies can lead to informed decisions, further maximizing operational uptime.

Understanding Hydraulic Valve Types: Selecting the Right One for Your Application

When it comes to hydraulic systems, selecting the right hydraulic valve type is crucial for optimizing performance and efficiency. Various valve types, including directional control valves, pressure relief valves, and flow control valves, each serve distinct functions tailored to specific applications. Directional control valves manage the flow direction of hydraulic fluid, making them essential in tasks requiring precise movement. Meanwhile, pressure relief valves safeguard the system from excessive pressure, ensuring safety and component longevity. Understanding these fundamental differences helps users choose the most suitable valve for their operations.

In addition to understanding valve functions, it's important to consider application-specific factors such as flow rate, pressure rating, and environmental conditions. For high-speed applications, proportional valves can provide fine control over flow rates, while check valves are ideal for preventing backflow in systems where the fluid direction must remain unidirectional. By carefully evaluating operational demands and matching them with the right valve type, businesses can enhance efficiency, reduce downtime, and extend the lifespan of their hydraulic systems.

Unlocking Efficiency: The Advantages of Hydraulic Valves in Modern Applications

| Hydraulic Valve Type | Advantages | Common Applications | Operating Pressure Range (psi) |

|---|---|---|---|

| Directional Control Valves | Precise flow direction control | Excavators, Forklifts | 1500 - 3000 |

| Pressure Control Valves | Maintains system pressure | Hydraulic presses, Lifting equipment | 1000 - 5000 |

| Flow Control Valves | Regulates flow rate | Agricultural equipment, Machine tools | 1000 - 4000 |

| Check Valves | Prevents backflow | Pipelines, Hydraulic circuits | 500 - 3000 |

| Relief Valves | Protects system from overload | Hydraulic systems, Industrial machines | 3000 - 7000 |

Analyzing the Impact of Hydraulic Valves on Energy Consumption and Cost Savings

Hydraulic valves play a crucial role in enhancing energy efficiency and cost savings in modern applications. By precisely controlling fluid flow, these valves optimize the performance of hydraulic systems, which is especially critical in industries such as heavy-duty mobile machinery and electro-hydraulic steering systems. Recent innovations, such as the microindependent metering (MIM), demonstrate significant improvements in actuator performance, leading to lower energy consumption and operational costs.

Tips for optimizing hydraulic valve performance include regular maintenance to ensure they operate at peak efficiency, and selecting valves that suit specific application needs to minimize energy waste. Implementing advanced systems like pump-controlled designs can also substantially improve energy usage, particularly in applications where high power is required.

Furthermore, integrating heat recovery and smart control systems can enhance the sustainability of hydraulic applications. By adopting these strategies, industries can not only reduce their environmental impact but also achieve considerable cost savings, positioning themselves for a more efficient future.

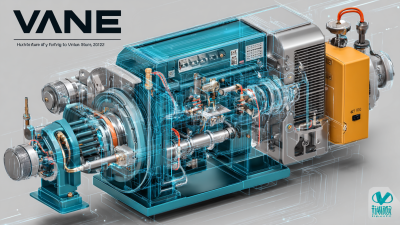

Future Trends: Innovations in Hydraulic Valve Technology for Modern Industries

In recent years, the hydraulic valve industry has witnessed significant developments that promise to enhance efficiency and performance across various sectors. Future trends highlight innovations such as smart hydraulic valves that integrate IoT technology. This allows for real-time monitoring and precise control, enabling industries to optimize their operations and reduce downtime. These advancements not only improve performance but also contribute to the sustainability goals by minimizing energy consumption.

Tip: When considering the implementation of hydraulic valves in your operations, look for systems that offer digital interfaces. This can provide insights into operational efficiencies and alert you to potential maintenance needs before they escalate.

Another intriguing trend is the use of advanced materials that enhance the durability and reliability of hydraulic valves. Innovations such as composite materials and coatings can significantly reduce wear and tear, making these valves more resilient to harsh conditions. This is particularly beneficial in industries like construction and aerospace, where performance under extreme conditions is crucial.

Tip: Regularly review the specifications and material properties of hydraulic valves to ensure they meet the demands of your specific application, thus maximizing longevity and performance.

Unlocking Efficiency: The Advantages of Hydraulic Valves in Modern Applications

Related Posts

-

What are the Advantages of Using the Best Hydraulic Valves in Your Operations

-

10 Top High Pressure Pump Innovations Transforming Industrial Efficiency in 2023

-

Navigating the Future of Vane Pumps in 2025 Top Technology Trends and How to Adapt Your Supply Chain

-

Understanding the Features of the Best Piston Pump for Global Buyers

-

Navigating Global Standards for Best Pressure Pumps Compliance and Import Certification Guide

-

7 Reasons Why the Best High Pressure Pump is Essential for Your Industrial Operations