- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

Exploring Alternatives to Best Hydraulic Motors for Global Sourcing Opportunities

In today's rapidly evolving manufacturing landscape, the quest for efficiency and reliability has led engineers and purchasing professionals to explore alternatives to the traditional best hydraulic motors. Hydraulic motors are integral components in various industries, driving everything from mobile machinery to industrial equipment. However, with the increasing demand for cost-effective solutions and sustainable practices, global sourcing opportunities are emerging that can challenge the dominance of conventional hydraulic motors. This guide will delve into the various alternatives available in the market, highlighting innovative technologies and sourcing strategies that not only meet operational needs but also align with modern business objectives. Whether you are seeking to enhance performance, reduce costs, or minimize environmental impact, understanding these alternatives can help make informed procurement decisions and position your operations for success in a competitive environment.

Benefits of Selecting the Right Hydraulic Motor for Your Business Needs

When it comes to optimizing your industrial operations, selecting the right hydraulic motor is crucial for ensuring efficiency and reliability. Hydraulic motors are central to various machines and systems, providing the necessary power to drive their components. By choosing a high-quality motor tailored to your specific business needs, you can significantly enhance productivity while reducing operational costs. Different applications may require unique characteristics, such as torque, speed, and size, making it vital to evaluate the performance parameters that align with your operational goals.

Additionally, the benefits of sourcing hydraulic motors through global channels extend beyond just acquiring the best products. Engaging with a diverse range of suppliers can enhance your access to innovative technologies and competitive pricing. By exploring alternatives in the global market, businesses can not only find motors that fit their technical specifications but also strengthen their supply chain resilience. Ultimately, making an informed decision about which hydraulic motor to integrate can lead to sustainable growth and improved project outcomes, providing a solid foundation for future success.

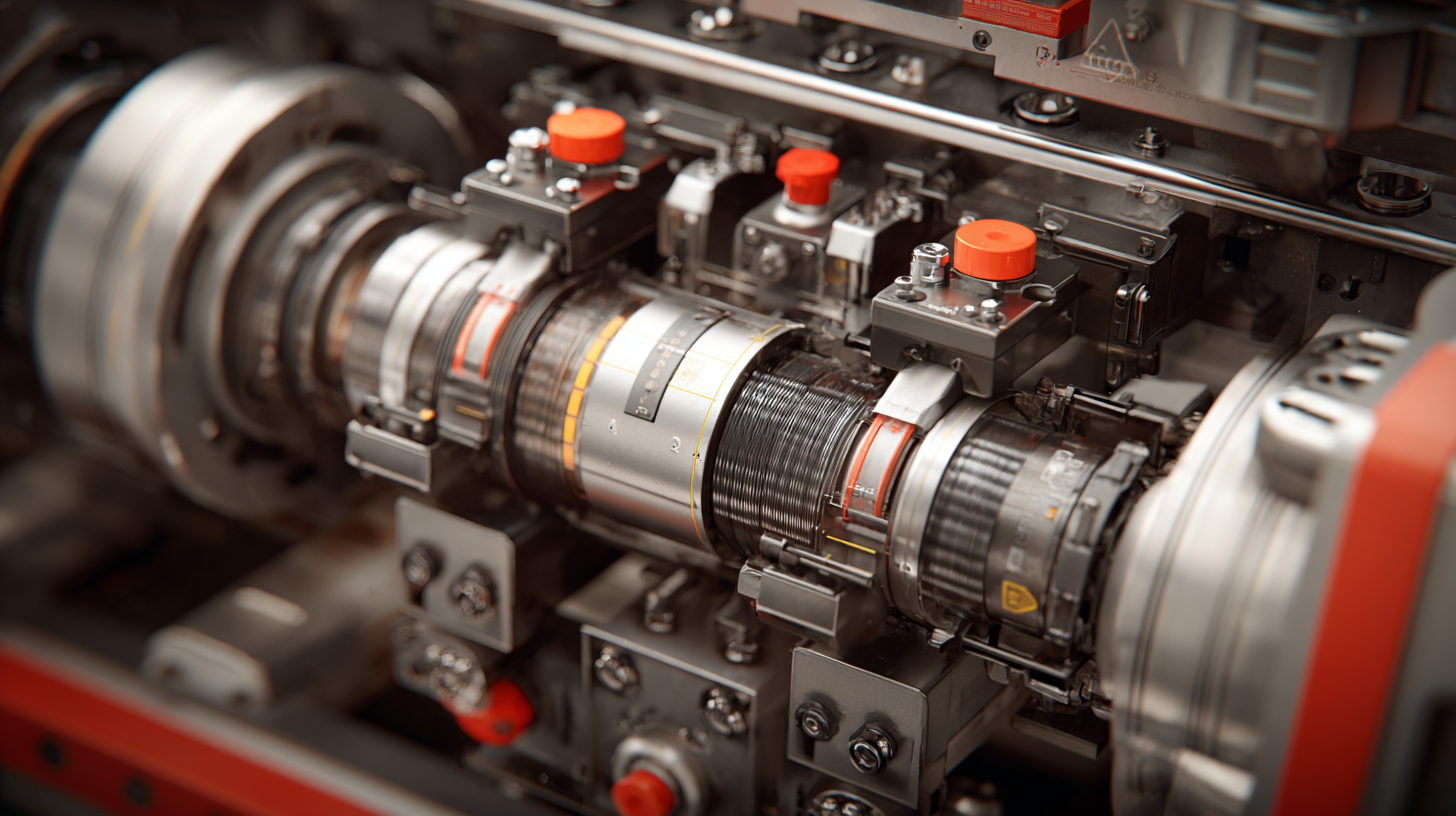

Comparison of Hydraulic Motor Efficiency by Type

This bar chart illustrates the efficiency of various types of hydraulic motors commonly used in industrial applications. Selecting the right hydraulic motor can significantly impact your business operations by improving efficiency and reducing costs.

Cost-Effectiveness: Maximizing Value through Alternative Hydraulic Motor Types

The growing need for cost-effective solutions in various industries has led to an increased interest in alternative hydraulic motors. These alternatives can not only provide increased value but also enhance overall efficiency. Understanding the diverse types of hydraulic motors—from gear motors to piston motors—enables businesses to select the right fit for their specific applications while maintaining budget constraints.

Tips for maximizing value through alternative hydraulic motors include thoroughly assessing the operational requirements of your machinery. It's crucial to match the motor type to your system’s needs, ensuring optimal performance. Moreover, consider investing in innovative technologies that can lower costs in the long run. For example, integrated hydraulic systems can reduce complexity and maintenance expenses.

Another tip is to explore the potential of hybrid systems that combine various energy sources. These systems can enhance performance and reliability while driving down operational expenditures. By staying informed about the latest advancements in hydraulic technology, businesses can make informed decisions that enable them to capitalize on cost-saving opportunities and improve their overall operational efficiency.

Exploring Alternatives to Best Hydraulic Motors for Global Sourcing Opportunities

| Motor Type | Efficiency (%) | Cost per Unit ($) | Applications | Maintenance (Frequency) |

|---|---|---|---|---|

| Gear Motor | 85 | 450 | Construction, Agriculture | Annual |

| Vane Motor | 80 | 400 | Automotive, Industrial | Biannual |

| Piston Motor | 90 | 600 | Marine, Aerospace | Quarterly |

| Swash Plate Motor | 88 | 550 | Manufacturing, Mining | Annually |

| Radial Piston Motor | 87 | 500 | Heavy Machinery, Oil & Gas | Several Times a Year |

Evaluating Performance: How Different Hydraulic Motors Enhance Efficiency

When evaluating the performance of hydraulic motors, it's crucial to understand how different designs and technologies can enhance efficiency in various applications. Hydraulic motors are essential components in numerous industries, driving machinery and equipment with precision and power. By comparing various types of hydraulic motors—such as gear, vane, and piston motors—manufacturers can identify the most suitable option for their specific operational needs, leading to improved performance and resource management.

Moreover, advancements in hydraulic motor technology have led to enhanced efficiency across the board. Modern solutions often incorporate features such as variable displacement, which allows for better flow control and energy conservation. Additionally, the integration of smart technologies, like IoT sensors, enables real-time monitoring and diagnostics, optimizing performance and minimizing downtime. As companies explore global sourcing opportunities, investing in the right hydraulic motor design will not only streamline operations but also contribute to sustainable practices by reducing energy consumption and waste.

Sourcing Strategies: Finding the Best Hydraulic Motor Suppliers Globally

In today's competitive manufacturing landscape, sourcing the best hydraulic motors can significantly impact operational efficiency. According to a recent report by Market Research Future, the global hydraulic motor market is projected to reach $23 billion by 2027, growing at a CAGR of 5.4% from 2020. This robust growth emphasizes the importance of developing effective sourcing strategies to identify reliable suppliers who can provide high-quality hydraulic motors suited to specific application needs.

One successful approach is leveraging digital platforms and marketplaces to expand supplier options beyond local boundaries. A comprehensive analysis by Smithers Pira highlighted that companies utilizing e-sourcing can reduce procurement costs by up to 15%, allowing them to allocate resources toward innovation and quality improvement. Furthermore, collaborating with suppliers who demonstrate a commitment to sustainability can enhance brand reputation and ensure compliance with increasingly strict environmental regulations. By adopting forward-thinking sourcing strategies, manufacturers can tap into a global network of suppliers, ultimately leading to more efficient operations and improved product offerings.

Sustainability in Hydraulic Motors: Eco-Friendly Benefits to Consider

Sustainability has become a critical factor in the design and manufacturing of hydraulic motors. As industries increasingly seek eco-friendly solutions, the hydraulic motor sector is responding with innovative materials and technologies that minimize environmental impact. According to a recent report from the International Energy Agency (IEA), adopting sustainable practices in hydraulic systems can lead to energy savings of up to 30%, significantly reducing the carbon footprint of industrial operations.

When exploring eco-friendly hydraulic motors, consider options that utilize recycled materials or have been designed for enhanced energy efficiency. These innovations not only contribute to sustainability but can also result in long-term cost savings. For instance, a study by the Hydraulic Institute found that motors designed with energy-efficient features can reduce operational costs by nearly $100,000 over their lifespan, making them an attractive option for businesses.

Tips for sourcing sustainable hydraulic motors include researching manufacturers who adhere to international environmental standards and prioritizing products that have reliable certifications. Additionally, engaging in partnerships with companies committed to sustainability can enhance your supply chain's eco-efficiency. By making informed choices, businesses can play a vital role in promoting responsible manufacturing practices while benefitting economically.