- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

Top 10 Benefits of Using Rubber Pump Impellers for Efficiency?

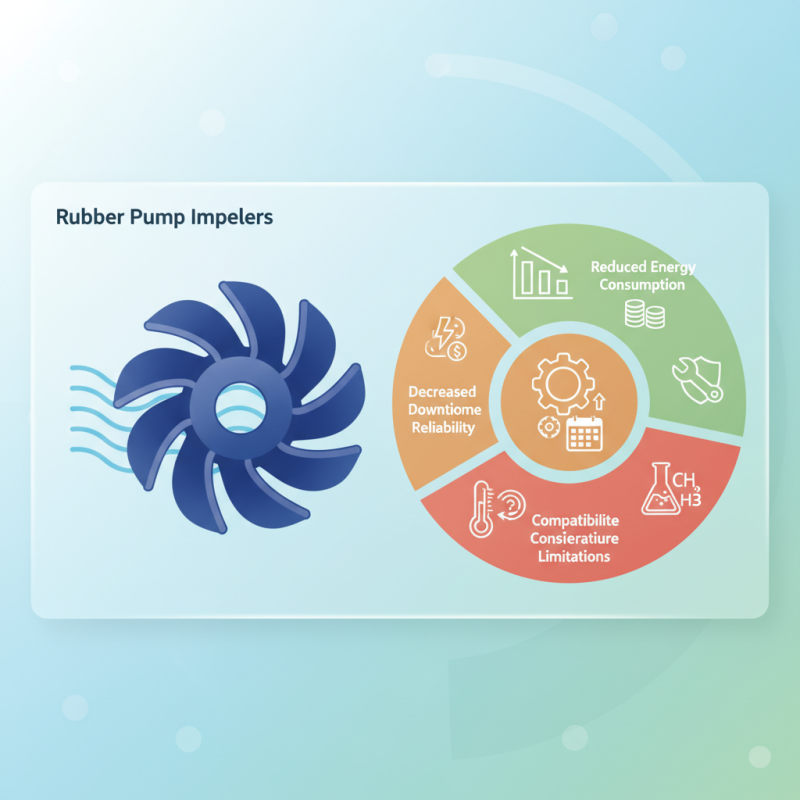

In today's industrial landscape, the efficiency of fluid transfer systems is crucial. The choice of components can significantly impact performance. One key component is the Rubber Pump Impeller. Using rubber materials in pump impellers offers unique advantages. According to recent industry reports, rubber impellers reduce energy consumption by up to 15%. This improvement can lead to significant cost savings for manufacturers.

Rubber Pump Impellers excel in various applications, from wastewater treatment to chemical processing. They demonstrate superior wear resistance and flexibility compared to traditional materials. Recent studies suggest that equipment downtime can decrease by 20% when utilizing rubber impellers. This reliability enhances overall operational efficiency. However, it's worth noting that not every application may benefit from rubber impellers. Careful evaluation is essential to ensure compatibility with specific fluid types and conditions.

Despite the strengths, some challenges remain. For example, higher temperatures can limit the performance of rubber components. Manufacturers must address these factors to maximize efficiency. Ultimately, understanding both the benefits and limitations of Rubber Pump Impellers can drive more informed decisions in industrial settings.

Advantages of Rubber Pump Impellers in Various Industries

Rubber pump impellers are increasingly popular in various industries. Their unique properties facilitate efficient fluid transportation. These impellers offer excellent resistance to wear. They can withstand harsh environments and aggressive chemicals. This durability leads to lower maintenance costs over time. Industries like agriculture and mining benefit significantly from these features.

Another advantage is their lightweight construction. This characteristic simplifies installation and reduces energy consumption. In food processing, rubber impellers prevent contamination. They are less likely to damage delicate products compared to metal options. However, rubber impellers can be sensitive to extreme temperatures, which is a limitation worth considering.

In wastewater management, these impellers demonstrate flexibility. They adapt well to varying flow rates and pressures. This adaptability can improve operational efficiency. Yet, users must monitor them regularly to avoid wear and tear. It's crucial to assess their performance in specific applications. This helps in identifying potential issues before they escalate.

Improved Durability and Longevity of Rubber Impellers

Rubber pump impellers have gained popularity due to their remarkable durability. Unlike traditional materials, rubber impellers resist wear and tear significantly. They can withstand harsh conditions without breaking down quickly. This leads to a much longer lifespan when compared to metal or plastic impellers.

Tips: When selecting rubber impellers, consider the operating environment. High temperatures and corrosive fluids can affect performance. Always check compatibility with the fluid being pumped. Remember, not all rubber grades are the same. Make sure to find one that fits your specific needs.

With increased longevity, rubber impellers also offer cost savings. Reduced replacement frequency means lower maintenance costs over time. However, some may have concerns about these materials in high-pressure systems. It’s essential to conduct proper assessments. Investing in quality may sometimes require a larger upfront cost, but it pays off in the long run. Prioritize research before making a decision.

Top 10 Benefits of Using Rubber Pump Impellers for Efficiency

| Benefit | Description | Efficiency Impact |

|---|---|---|

| Improved Durability | Rubber impellers are resistant to wear and tear, prolonging their lifespan. | Increased operational time between replacements, enhancing overall efficiency. |

| Corrosion Resistance | Rubber is less susceptible to corrosion, especially in harsh environments. | Reduction in maintenance costs and downtime. |

| Noise Reduction | Rubber impellers operate more quietly than metal alternatives. | Enhanced user comfort and regulatory compliance. |

| Lightweight Design | Rubber impellers are lighter than their metal counterparts. | Easier handling and installation leading to faster project completion. |

| Flexibility | Rubber can withstand a variety of pressure and flow conditions. | Enhanced adaptability in various operational environments. |

| Cost-Effective | Generally lower initial costs and good longevity. | Long-term savings on replacements and maintenance. |

| Fluid Compatibility | Rubber impellers can handle a wide range of fluids. | Versatile in industrial applications minimizing need for specialized components. |

| Easy Maintenance | Rubber impellers require less frequent maintenance. | Reduced labor and operational costs. |

| High Efficiency | Rubber impellers maintain efficiency at varying flow rates. | Consistent performance in dynamic conditions. |

| Temperature Resistance | High-quality rubber can withstand extreme temperatures. | Extends the range of applications across different climates. |

Enhanced Pump Efficiency Through Reduced Friction

The choice of impellers significantly impacts pump efficiency. Rubber pump impellers, known for their durability, reduce friction in a notable way. According to industry research, friction losses can account for up to 40% of energy in hydraulic systems. By minimizing these losses, rubber impellers enhance overall performance.

Rubber materials offer flexibility and resilience. They conform better to operational conditions, achieving a tighter seal. This sealing efficiency can further cut down on energy waste. A study published in the Journal of Fluid Mechanics found that using rubber impellers can lead to an efficiency increase of 20%. Such improvements are essential for industries reliant on continuous operation.

However, not all rubber impellers deliver the same results. Variations in formulation and design can affect performance. It’s crucial to evaluate specific applications and environments. Some users may find that not all rubber formulations withstand extreme conditions over time. The choice of material should reflect operational needs to avoid premature wear. Balancing efficiency with durability is an ongoing challenge.

Top 10 Benefits of Using Rubber Pump Impellers for Efficiency

Cost-Effectiveness of Rubber Impellers Compared to Metal Options

Rubber pump impellers are gaining attention for their cost-effectiveness. Compared to traditional metal options, they are lighter and more efficient. Studies show that rubber impellers can reduce energy consumption by up to 20%. This efficiency translates to lower operating costs for many industries.

The lifespan of rubber impellers often rivals that of metal alternatives. While metal may initially seem durable, rubber offers resistance to corrosion and wear. A report from the Pump Manufacturers Association indicates that rubber impellers can last 15-20% longer in harsh environments. These facts suggest that long-term savings may outweigh initial investments.

However, some users may find rubber impellers less effective in extreme conditions. The trade-off between flexibility and durability can spark debate. Manufacturers must focus on quality to avoid premature wear. Choosing the right impeller material is crucial for maintaining optimal pump efficiency.

Ease of Maintenance and Replacement for Rubber Impellers

Rubber pump impellers are widely recognized for their ease of maintenance and replacement. The flexibility of rubber allows for straightforward disassembly without the need for special tools. This feature saves time, which is crucial in industries where downtime translates to significant financial losses. According to a 2022 industry report, nearly 30% of maintenance costs can be attributed to complicated replacement procedures.

Moreover, the simplicity of replacing rubber impellers means that staff training can be less intensive. This is particularly beneficial for operations that rely on a smaller team. Improper installation is a common concern with pump components; however, rubber impellers’ design mitigates many installation errors made with rigid materials. Certain studies suggest that the error rate can drop by 15% with rubber designs.

While rubber impellers are easy to maintain, they are not without their drawbacks. Over time, rubber can degrade, especially in high-temperature or chemical environments. This necessitates regular inspections that some operators may overlook. Neglecting these checks can lead to performance issues and ultimately higher operating costs. Regular monitoring is vital for optimal efficiency and longevity.