- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

How to Choose the Right Gear Pump for Your Industrial Needs

Choosing the right gear pump for your industrial needs is critical for optimizing efficiency and performance in various applications. According to the latest market reports, the global gear pump market is expected to reach USD 3.6 billion by 2026, growing at a CAGR of 4.8% from 2021 to 2026. This growth is driven by the increasing demand for enhanced pumping solutions in sectors such as oil and gas, chemicals, and manufacturing. Gear pumps are renowned for their ability to handle high-viscosity fluids and provide precise flow rates, making them indispensable in many industrial processes. However, with a plethora of options available, selecting the right gear pump requires careful consideration of factors such as fluid compatibility, operational parameters, and maintenance needs. This guide aims to provide essential insights that will empower businesses to make informed decisions in their gear pump selection process, ensuring optimal functionality and cost-effectiveness in their operations.

Identifying Your Industry Specific Requirements for Gear Pumps

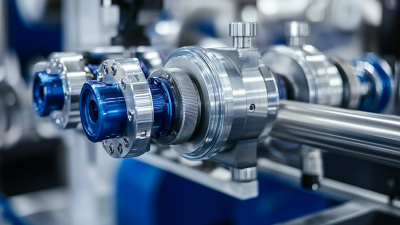

When selecting a gear pump for your industrial applications, it's crucial to identify the specific requirements of your industry. Different sectors, such as oil and gas, food and beverage, or chemical manufacturing, have unique demands that can greatly influence the type of gear pump needed. For instance, the viscosity of the fluids being pumped may vary significantly between industries, and gear pumps must be capable of efficient operation under these varying conditions. Assessing the fluid properties, including temperature, pressure, and chemical compatibility, will help in selecting the right materials and design features for optimal performance.

Additionally, operational factors such as flow rate and pressure requirements must be taken into account. Each industry typically has standard operational benchmarks that dictate the minimum and maximum flow rates needed for efficiency and safety. Understanding these parameters ensures that the chosen gear pump can meet the necessary performance criteria without risking equipment failure or downtime. Therefore, a thorough analysis of your industry’s specific requirements is fundamental in making an informed decision that aligns with operational goals and enhances overall productivity.

Understanding Different Types of Gear Pumps and Their Applications

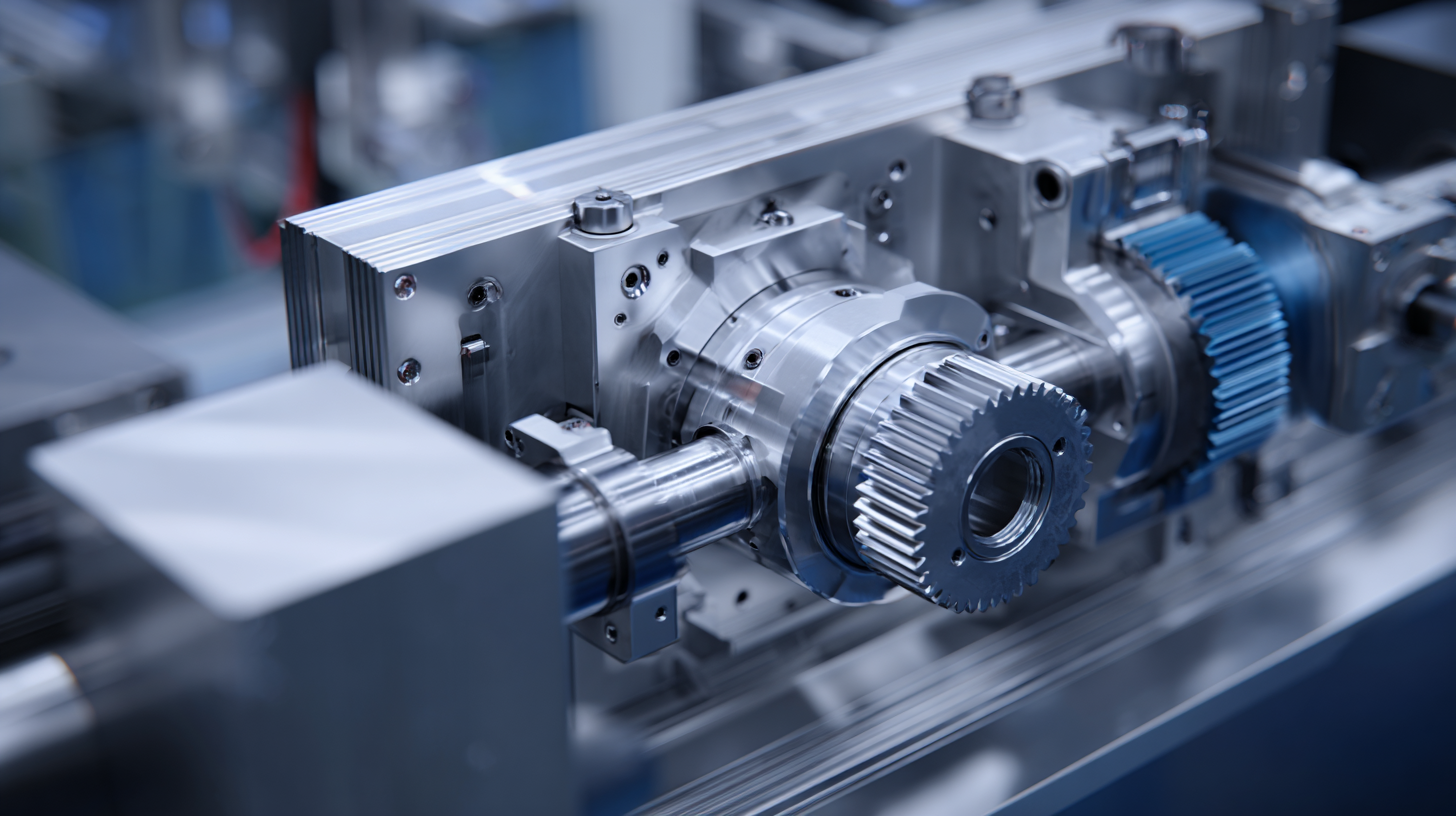

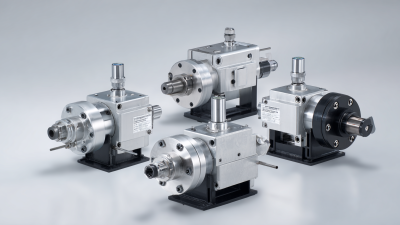

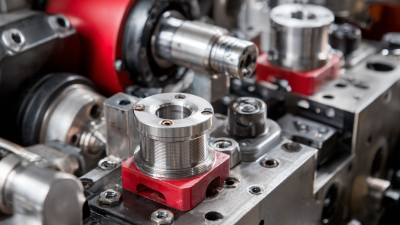

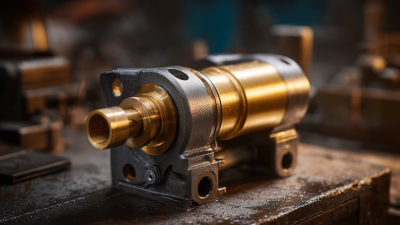

When selecting a gear pump for industrial applications, understanding the different types available is crucial. There are primarily two categories of gear pumps: external gear pumps and internal gear pumps. External gear pumps consist of two rotating gears that create a flow by trapping fluid between the gear teeth and the pump casing. They are ideal for pumping low-viscosity fluids but may not handle shear-sensitive liquids well. Alternatively, internal gear pumps feature one gear rotating within another, providing a more efficient design for handling a wider range of viscosities, including thick and shear-sensitive fluids.

Applications of gear pumps vary significantly based on their design and capabilities. For instance, external gear pumps are commonly employed in hydraulic systems and fuel transfer operations, where consistent flow rates are essential. On the other hand, internal gear pumps excel in handling demanding fluid transfer situations like asphalt or viscous chemicals, where their ability to maintain pressure is beneficial. By carefully assessing the specific requirements of your application, such as fluid type, viscosity, and flow rate, you can ensure the selection of the right gear pump that meets your industrial needs effectively.

How to Choose the Right Gear Pump for Your Industrial Needs

| Pump Type | Viscosity Range (cP) | Pressure Range (psi) | Typical Applications | Advantages |

|---|---|---|---|---|

| External Gear Pump | 1 - 5000 | 0 - 3000 | Hydraulic fluids, lubricating oils | High efficiency, smooth flow |

| Internal Gear Pump | 500 - 10000 | 0 - 2500 | Viscous fluids, chemical processing | Compact design, can handle shear-sensitive fluids |

| Gear Pump with Magnetic Drive | 1 - 1000 | 0 - 2000 | Chemical handling, petroleum products | Leak-free operation, reduced maintenance |

| Composite Gear Pump | 10 - 3000 | 0 - 1500 | Paints, inks, adhesives | Reduced weight, good corrosion resistance |

Evaluating Key Performance Factors for Gear Pump Selection

When selecting a gear pump for industrial applications, evaluating key performance factors is crucial for ensuring optimal functionality and efficiency. One of the primary aspects to consider is the pump's flow rate, which is often determined by the size of the gears and their rotational speed. According to a report by the Hydraulic Institute, pumps with a higher flow rate can increase productivity by up to 15% in high-demand sectors. However, it is important to balance flow rate with system pressure requirements to avoid cavitation or excessive wear.

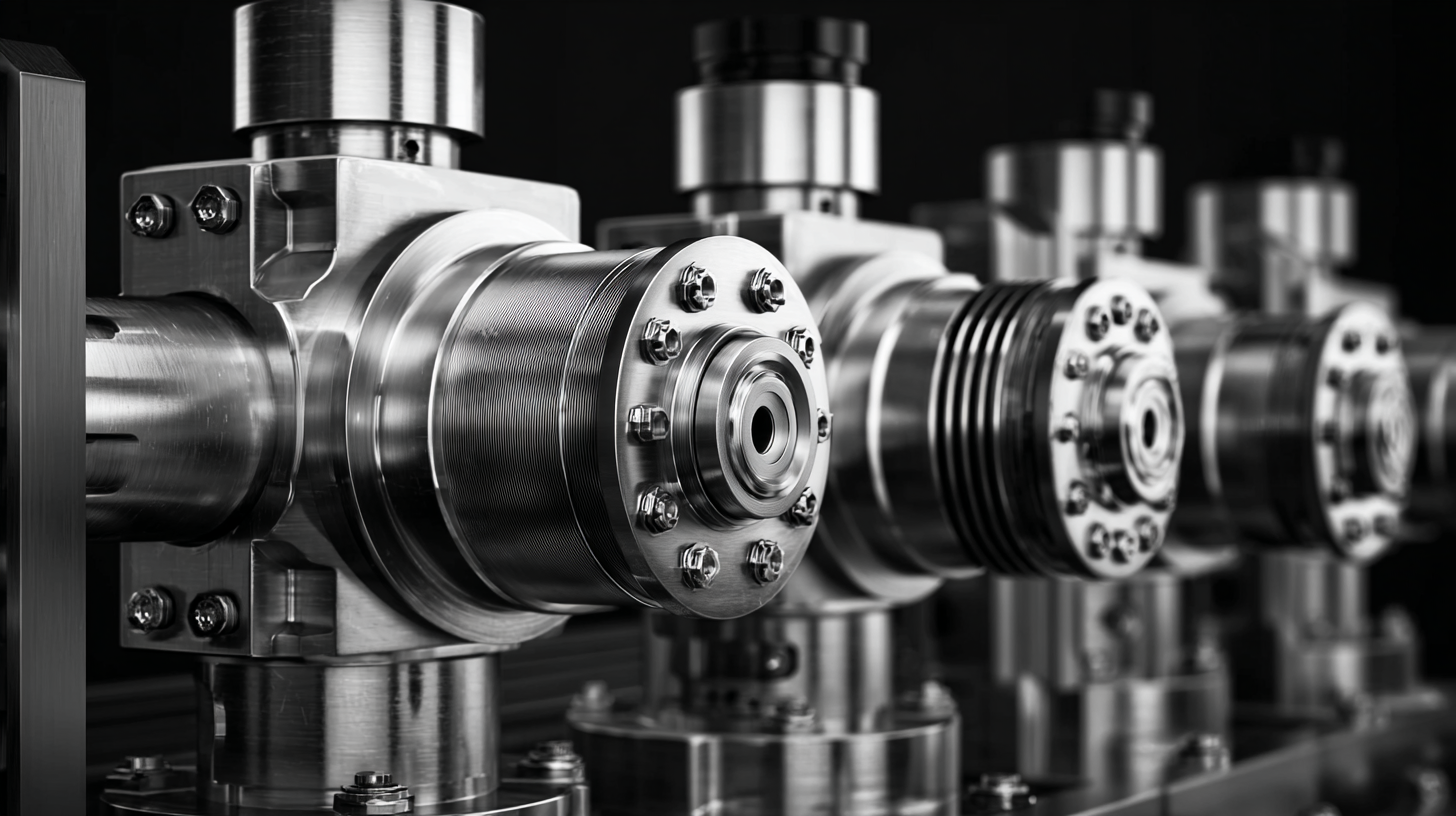

Another critical factor is the material composition of the gear pump, which impacts durability and resistance to corrosive fluids. The report emphasizes that using pumps made from advanced materials, like duplex stainless steel, can extend service life by an average of 30% in harsh environments. Lastly, the efficiency of the pump, typically measured by its volumetric and mechanical efficiency ratings, should be assessed. A study conducted by the American Society of Mechanical Engineers (ASME) indicates that selecting a pump with at least 90% efficiency can lead to significant energy savings, ultimately reducing operational costs. By carefully considering these performance factors, industries can choose gear pumps that not only meet their specific needs but also enhance overall system performance.

Assessing Material Compatibility and Environmental Considerations

When selecting a gear pump for industrial applications, assessing material compatibility and environmental considerations is crucial for optimal performance and longevity. Gear pumps are commonly used to transfer fluids, and the materials used in their construction must be compatible with the fluids being handled. For instance, if pumping corrosive substances, choosing a pump made from stainless steel or specialized alloys is essential to prevent deterioration and maintain efficiency. Additionally, if the fluids are viscous or contain abrasive particles, the pump's internal materials must be robust enough to withstand wear over time.

Environmental considerations also play a significant role in gear pump selection. Factors such as temperature fluctuations, exposure to chemicals, and operating conditions must be evaluated. For example, if the gear pump will be used in an environment with extreme temperatures, the seals and lubricants must be selected to perform reliably under those conditions. Furthermore, compliance with environmental regulations regarding fluid containment and emissions is vital, ensuring that the pump aligns with industry standards while minimizing the risk of environmental contamination. By carefully assessing these factors, businesses can enhance operational efficiency and reduce the likelihood of maintenance issues in the long run.

Cost vs. Quality: Finding the Right Balance for Your Gear Pump Investment

When selecting a gear pump for industrial applications, achieving the right balance between cost and quality is crucial. Initially, it may seem appealing to choose the least expensive option available, but sacrificing quality can lead to long-term issues such as increased maintenance costs and operational inefficiencies. A well-constructed gear pump will not only perform better but will also have a longer lifespan, thereby justifying a higher initial investment.

Quality gear pumps typically come with better materials that can withstand harsh conditions and maintain their efficiency over time. Additionally, they often offer enhanced performance characteristics such as better flow rates and pressure capabilities. It's essential to evaluate your specific operational needs against the pump's specifications.

Investing in quality might have a higher upfront cost, but the potential savings in repairs, downtime, and energy consumption can make it a more economical choice in the long run. Hence, finding that delicate balance between cost and quality ensures that your industrial operations remain efficient and reliable.

Related Posts

-

Unlocking Efficiency: The Advantages of Choosing the Best Gear Pumps for Your Business

-

7 Strategies from Best Pump Manufacturers to Boost Your Efficiency

-

Ultimate Guide to Comparing the Best Hydraulic Vane Pumps for Global Buyers

-

Discover Cutting-Edge Hydraulic Control Valve Innovations at the Upcoming 138th Canton Fair!

-

7 Reasons Why Best Hydraulic Pump Parts Enhance Equipment Efficiency

-

Exploring Innovative Alternatives to Best Piston Pump for Enhanced Efficiency and Performance