- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

Why Choosing the Right Piston Pump Can Enhance Your Industrial Efficiency

In the realm of industrial machinery, the selection of the appropriate piston pump plays a pivotal role in the overall efficiency of operations. As industries strive to optimize productivity and reduce operational costs, the function and quality of piston pumps cannot be overstated. According to Dr. Emily Carter, a leading expert in fluid dynamics and pump technology, “A well-chosen piston pump not only maximizes output but also minimizes energy consumption, resulting in a smarter, more sustainable operation.” This statement encapsulates the essence of why meticulous consideration must be given to the type of piston pump selected for specific applications.

The intricacies of piston pump performance can significantly influence various industrial processes, from manufacturing to chemical handling. With advancements in pump technology, the options available in the market continue to expand, making it crucial for industries to comprehend the implications of their choices. Understanding the diverse types of piston pumps and their operational characteristics is integral to enhancing industrial efficiency. Whether it’s for high-pressure applications or handling viscous fluids, the right piston pump can streamline processes and ultimately contribute to the bottom line.

In this discussion, we will delve into the critical factors that should guide the selection of piston pumps and how these decisions affect industrial performance.

Understanding the Role of Piston Pumps in Industrial Applications

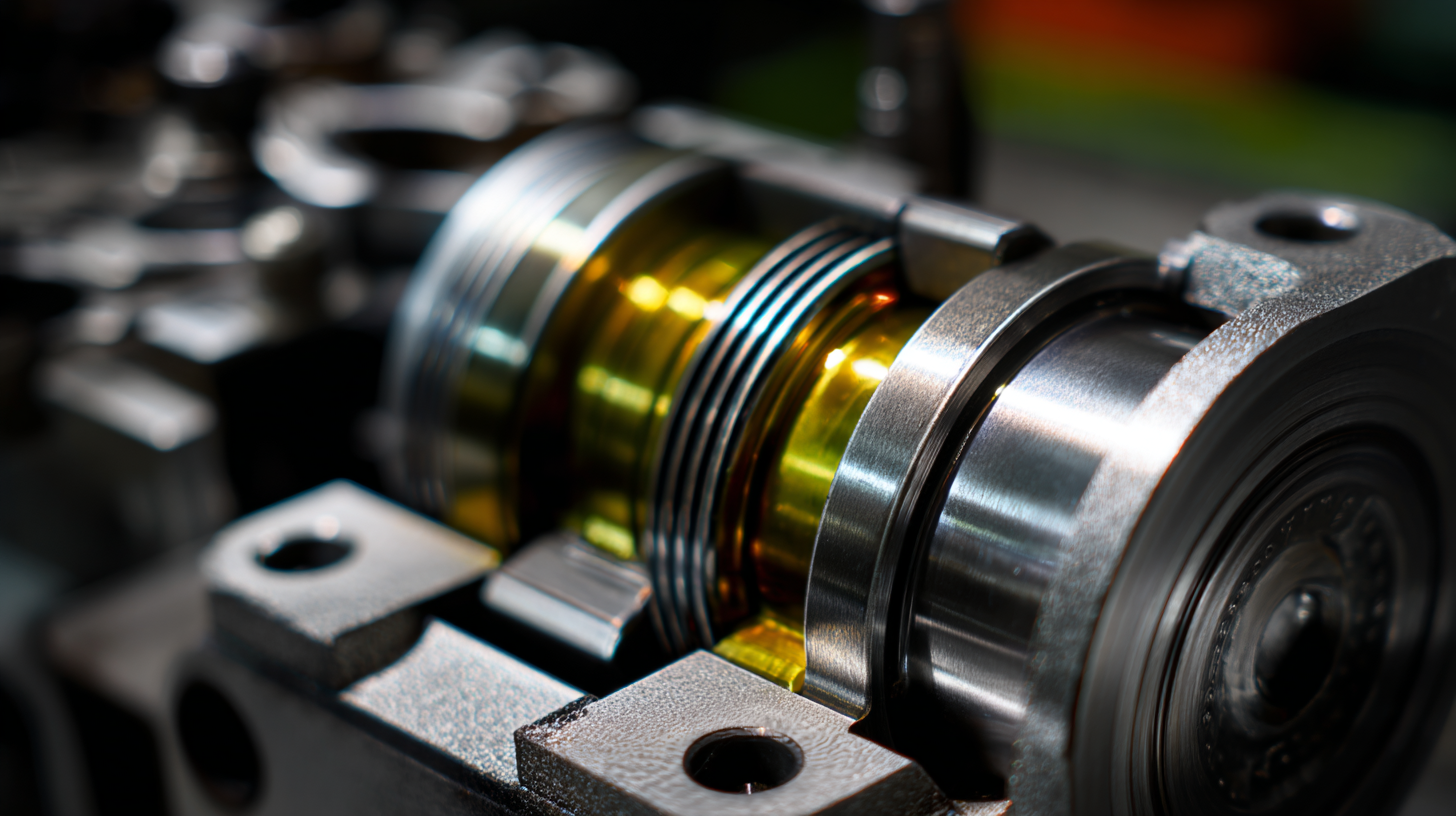

Piston pumps play a crucial role in various industrial applications by delivering high efficiency and precise fluid transfer. These pumps operate by using a piston mechanism that creates a vacuum to draw fluid into a chamber and then forces it out under pressure. This design allows for a consistent and controllable flow rate, making them ideal for tasks that require a predictable and stable output, such as in hydraulic systems, water treatment processes, and chemical manufacturing. Understanding the working principles of piston pumps can significantly enhance operational efficiency, as they can often handle a wide range of fluids with varying viscosities and temperatures.

Piston pumps play a crucial role in various industrial applications by delivering high efficiency and precise fluid transfer. These pumps operate by using a piston mechanism that creates a vacuum to draw fluid into a chamber and then forces it out under pressure. This design allows for a consistent and controllable flow rate, making them ideal for tasks that require a predictable and stable output, such as in hydraulic systems, water treatment processes, and chemical manufacturing. Understanding the working principles of piston pumps can significantly enhance operational efficiency, as they can often handle a wide range of fluids with varying viscosities and temperatures.

Moreover, the versatility of piston pumps allows them to be tailored for specific applications, further increasing their effectiveness in industrial setups. For example, by selecting the right materials for the pump components, manufacturers can optimize performance for corrosive or abrasive substances. Additionally, advancements in piston pump technology, including variable displacement pumps and electronic controls, have enabled better efficiency and energy savings. In industries where uptime is critical, investing in the right type of piston pump can lead to reduced maintenance costs and less downtime, ultimately improving overall productivity and operational efficiency.

Key Factors to Consider When Selecting a Piston Pump

When selecting a piston pump for industrial applications, several key factors can significantly enhance efficiency and performance. Accurately matching the pump type to its intended application is crucial. Piston pumps are highly effective in handling viscous fluids and can maintain consistent flow rates under varying operational conditions. According to recent industry studies, optimizing the selection process can result in efficiency improvements of up to 30%, translating into significant cost savings over time.

Another important factor to consider is the pump’s design and robustness. Advanced models incorporate features such as digital controls for improved accuracy and reliability, essential for applications in industries like pharmaceuticals, where precise dosing is critical. A report indicates that improper pump selection can lead to a staggering increase in maintenance costs—by as much as 25%—and can negatively impact production timelines. Therefore, investing time upfront in evaluating the right piston pump based on specific application requirements is paramount.

Benefits of High-Quality Piston Pumps for Operational Efficiency

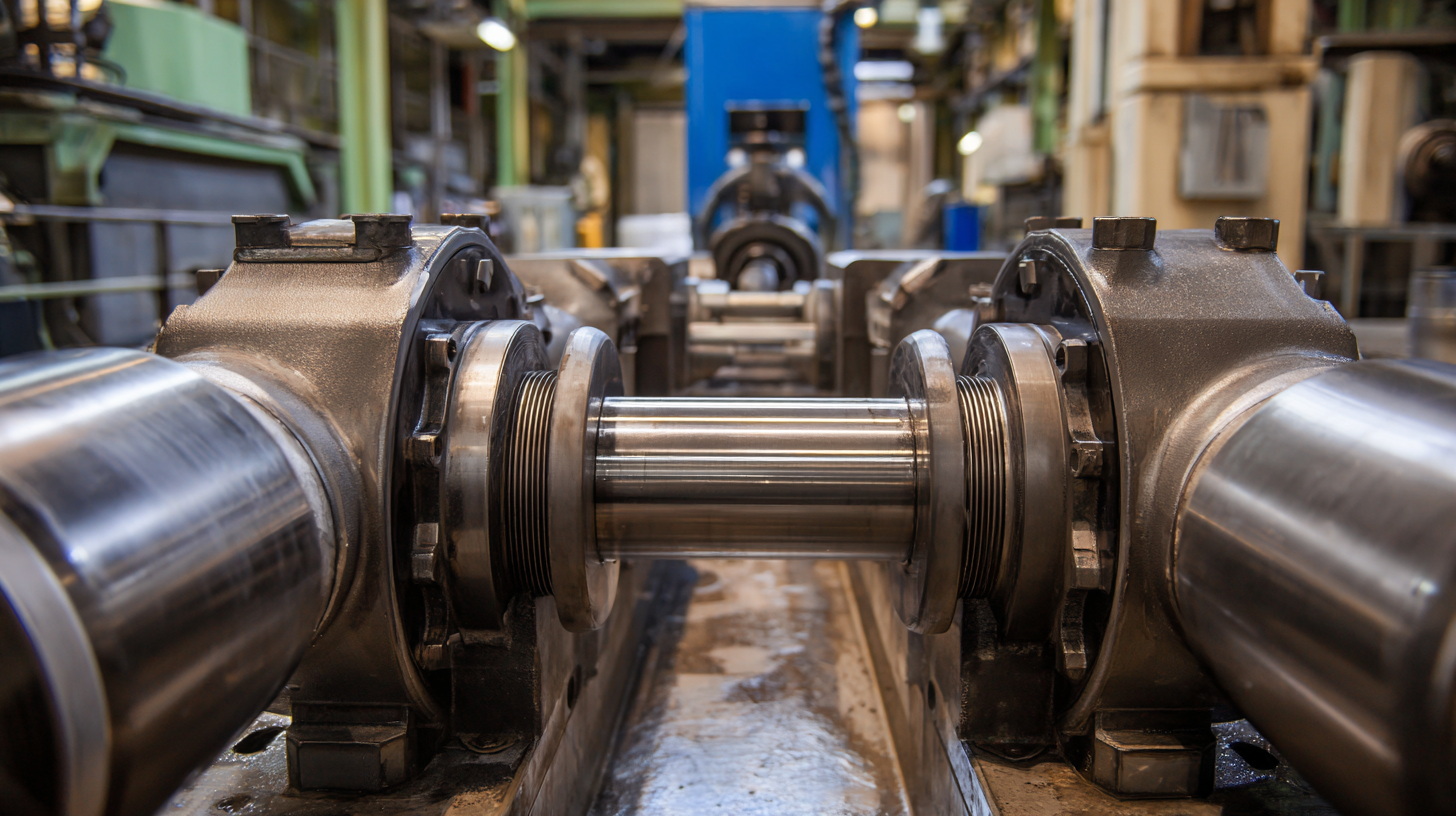

High-quality piston pumps play a crucial role in enhancing operational efficiency across various industries. According to a report by the Hydraulic Institute, the right selection of pumps can improve energy efficiency by up to 15%, significantly reducing operational costs. These pumps are designed to handle high-pressure applications and provide consistent flow rates, which are essential for processes in sectors such as manufacturing, agriculture, and oil and gas.

Moreover, piston pumps are known for their durability and reliability. Research conducted by the American Society of Mechanical Engineers indicates that well-maintained piston pumps can last up to 30% longer than lower-quality alternatives. This extended lifespan not only leads to fewer replacements but also minimizes downtime, allowing for uninterrupted production cycles. Industries leveraging high-quality piston pumps often report enhanced productivity and reduced maintenance costs, underscoring the importance of investing in superior pumping solutions for optimal performance.

Why Choosing the Right Piston Pump Can Enhance Your Industrial Efficiency - Benefits of High-Quality Piston Pumps for Operational Efficiency

| Benefit | Description | Impact on Efficiency |

|---|---|---|

| Increased Reliability | High-quality piston pumps reduce the risk of downtime due to mechanical failures. | Ensures continuous operation and higher productivity. |

| Enhanced Performance | Optimized design improves flow rates and pressure efficiency. | Leads to faster processing times in operations. |

| Energy Efficiency | High-quality pumps are designed to minimize energy consumption. | Reduces operational costs and carbon footprint. |

| Versatility | Can accommodate various fluid viscosities and types. | Enhances adaptability to different industrial processes. |

| Low Maintenance Costs | Quality materials and construction lead to fewer repairs. | Allows for cost savings over the pump's lifecycle. |

Common Mistakes to Avoid When Choosing Piston Pumps

When selecting a piston pump for industrial applications, avoiding common mistakes can significantly enhance operational efficiency. One prevalent error is underestimating the pump's capacity requirements. According to a report by the Hydraulic Institute, 30% of pump failures are related to improper sizing, which leads to inefficient performance and increased energy consumption. It is crucial to carefully calculate the desired flow rate and pressure before making a selection, ensuring that the pump meets the specific demands of the system.

Another frequent mistake is neglecting to consider the fluid characteristics that the pump will be handling. A study from the American Society of Mechanical Engineers (ASME) highlights that choosing the wrong material or pump type for specific fluids can result in equipment corrosion or premature wear. Factors such as viscosity, temperature, and chemical compatibility must be thoroughly assessed to avoid costly downtime and maintenance. Ensuring proper compatibility not only extends the lifespan of the pump but also maximizes the overall efficiency of the industrial process.

Maintenance Tips to Maximize Your Piston Pump's Performance

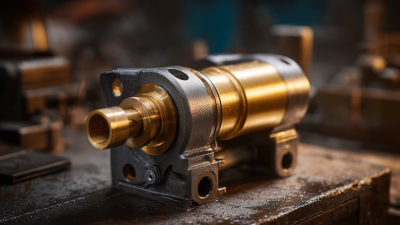

When it comes to maintaining the performance of your piston pump, regular upkeep is essential. One crucial tip is to frequently check and replace the seals and lubrication. Properly maintained seals ensure that there are no leaks, which can lead to efficiency drops and increased operational costs. Regular lubrication also assists in minimizing wear on moving parts, prolonging the life of the pump.

Another important aspect is keeping an eye on the pump's fluid levels and cleanliness. Contaminants in the fluid can cause premature wear or even catastrophic failures. Using proper filtration systems and routinely inspecting the fluid can help in maintaining the pump's integrity. Additionally, it's wise to create a routine maintenance schedule to perform checks and servicing consistently, preventing small issues from escalating into major problems.

Lastly, proper alignment and installation of the piston pump is pivotal. Misalignment can result in unnecessary strain on the components, leading to a decline in performance and efficiency. Make sure to follow the manufacturer's recommendations and have skilled technicians perform installations and realignments to ensure optimal operation. Following these tips will pave the way for enhanced efficiency and reliability in your industrial applications.

Impact of Piston Pump Maintenance on Efficiency

Related Posts

-

Understanding the Features of the Best Piston Pump for Global Buyers

-

Exploring Innovative Alternatives to Best Piston Pump for Enhanced Efficiency and Performance

-

10 Top High Pressure Pump Innovations Transforming Industrial Efficiency in 2023

-

Top 10 Hydraulic Manufacturers from China at the 137th Canton Fair

-

Navigating Global Standards for Best Pressure Pumps Compliance and Import Certification Guide

-

What are the Advantages of Using the Best Hydraulic Valves in Your Operations