- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

Solving Common Issues with Hydraulic Pump Motors for Global Buyers

In today's competitive global market, understanding the intricacies of hydraulic pump motors is essential for manufacturers, engineers, and buyers alike. Hydraulic pump motors play a critical role in numerous industrial applications, powering machinery and equipment across various sectors. However, despite their importance, common issues can arise, leading to inefficiencies and potential downtimes. This blog aims to address these prevalent problems, offering insights and practical solutions that can assist global buyers in making informed decisions. By exploring specific examples of issues encountered with hydraulic pump motors, we will provide valuable guidance on troubleshooting techniques and preventive measures to enhance the reliability and performance of these vital components.

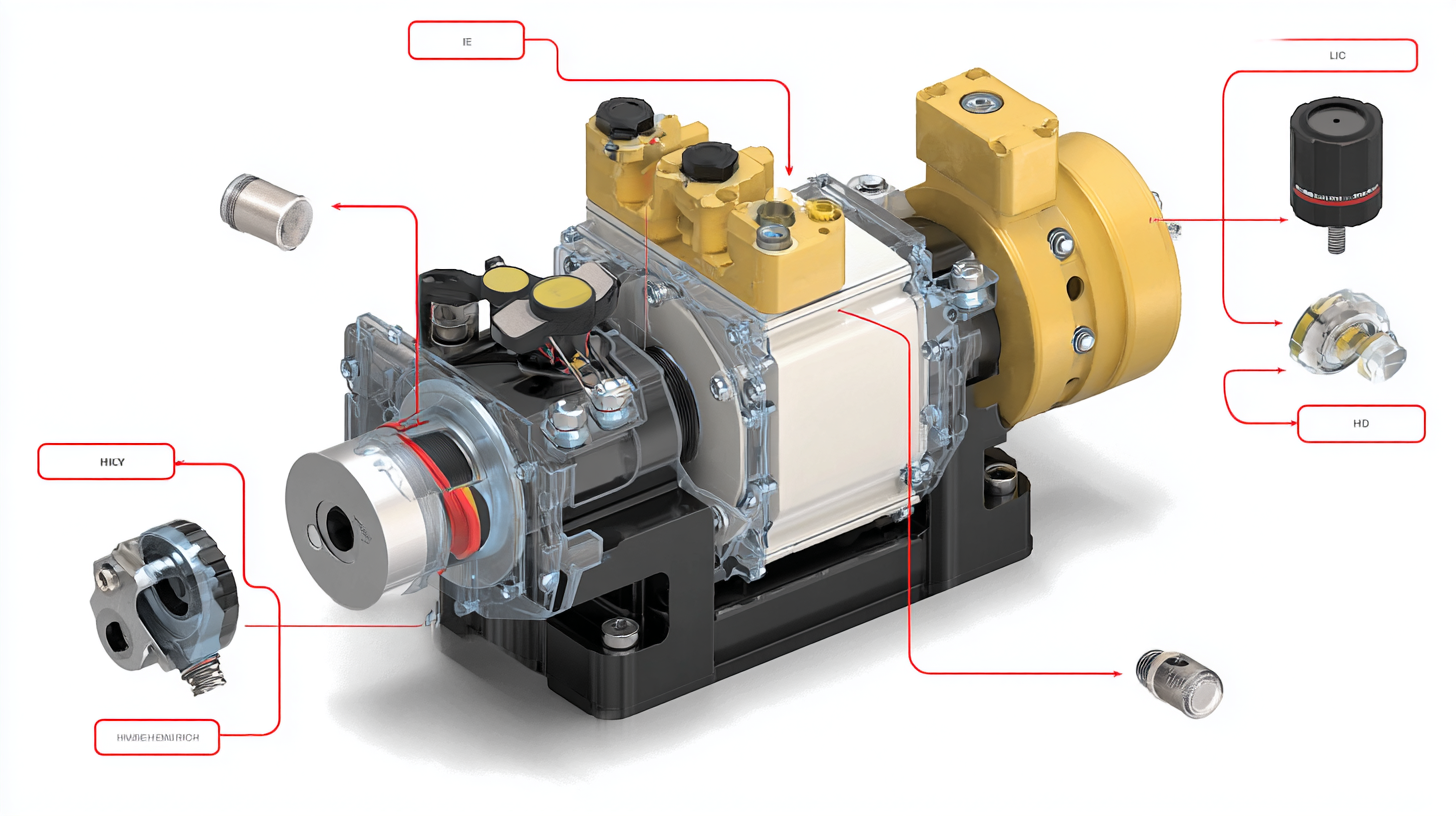

Understanding Hydraulic Pump Motors: Key Components and Their Functions

Hydraulic pump motors are crucial components in various industrial applications, converting hydraulic energy into mechanical energy. Understanding their key components—such as the hydraulic pump, motor, and the coupling mechanism—is essential for optimizing performance and reliability. According to recent industry reports, the global hydraulic pump market is expected to reach $56 billion by 2025, highlighting the increasing demand for efficient hydraulic systems.

A major component, the hydraulic pump, is responsible for generating flow and pressure, with standards indicating that a well-maintained pump can operate at 90% efficiency or higher. The motor then drives this pump, with electric and diesel options prevalent in various sectors. Ensuring the proper selection and maintenance of these components can significantly reduce operational costs.

Tip: Regularly check the fluid levels and quality to prevent pump wear and system failure. Additionally, consider implementing preventive maintenance schedules to extend the lifespan of hydraulic systems. Keeping an eye on temperature and pressure parameters is crucial, as deviations may signal underlying issues that need immediate attention.

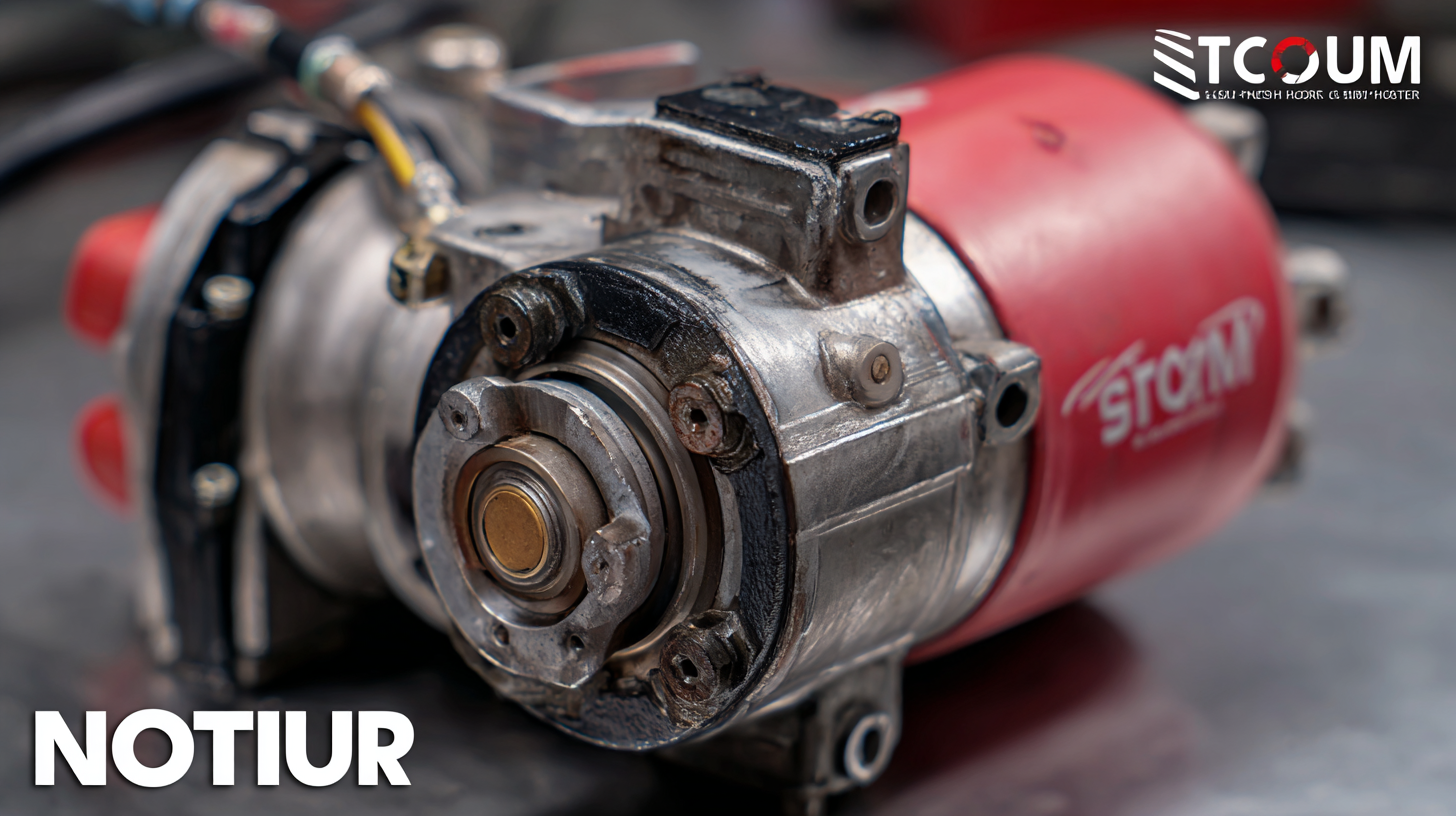

Common Hydraulic Pump Motor Failures and How to Diagnose Them

Hydraulic pump motors are essential components in various industrial applications, yet they frequently encounter specific failures that can disrupt operations. Common issues often arise from wear and tear, improper installation, lack of maintenance, and operational extremes. Understanding how to diagnose these failures is crucial for global buyers. Techniques like extreme-point symmetric mode decomposition combined with random forests represent advanced methods for fault diagnosis in systems such as axial piston pumps, allowing for precise identification of underlying issues.

Furthermore, implementing predictive maintenance practices can significantly minimize downtime. By utilizing remote monitoring systems to detect anomalies before they lead to machinery failure, operators can preemptively address faults. Recent studies have highlighted the effectiveness of analytical tools in ranking diagnostic signals, which aids in isolating critical features that can lead to timely interventions. This proactive approach not only enhances the longevity of hydraulic pump motors but also ensures their optimal performance, thereby safeguarding productivity in demanding environments.

Top Maintenance Tips for Ensuring Optimal Performance of Hydraulic Pump Motors

Hydraulic pump motors are essential components in various industries, ensuring efficient fluid power transmission. To maintain their optimal performance, it is crucial to follow specific maintenance practices. Regular inspection and monitoring can help identify potential issues before they become significant problems.

One effective tip is to always check the hydraulic fluid levels and quality. Low or contaminated fluid can lead to overheating and reduced efficiency. Regularly replacing the hydraulic fluid according to the manufacturer’s guidelines ensures that the system operates smoothly. Additionally, ensure that the filters are clean and replaced frequently to prevent dirt and debris from causing damage.

Another important maintenance tip is to inspect the connections and seals for any signs of leaks. Even minor leaks can lead to performance issues and increase operational costs. Using the correct tools to tighten connections and replace worn-out seals promptly can help maintain system integrity. Moreover, implementing a routine maintenance schedule allows for consistent monitoring of the hydraulic pump motor's performance, prolonging its lifespan and ensuring reliable operation.

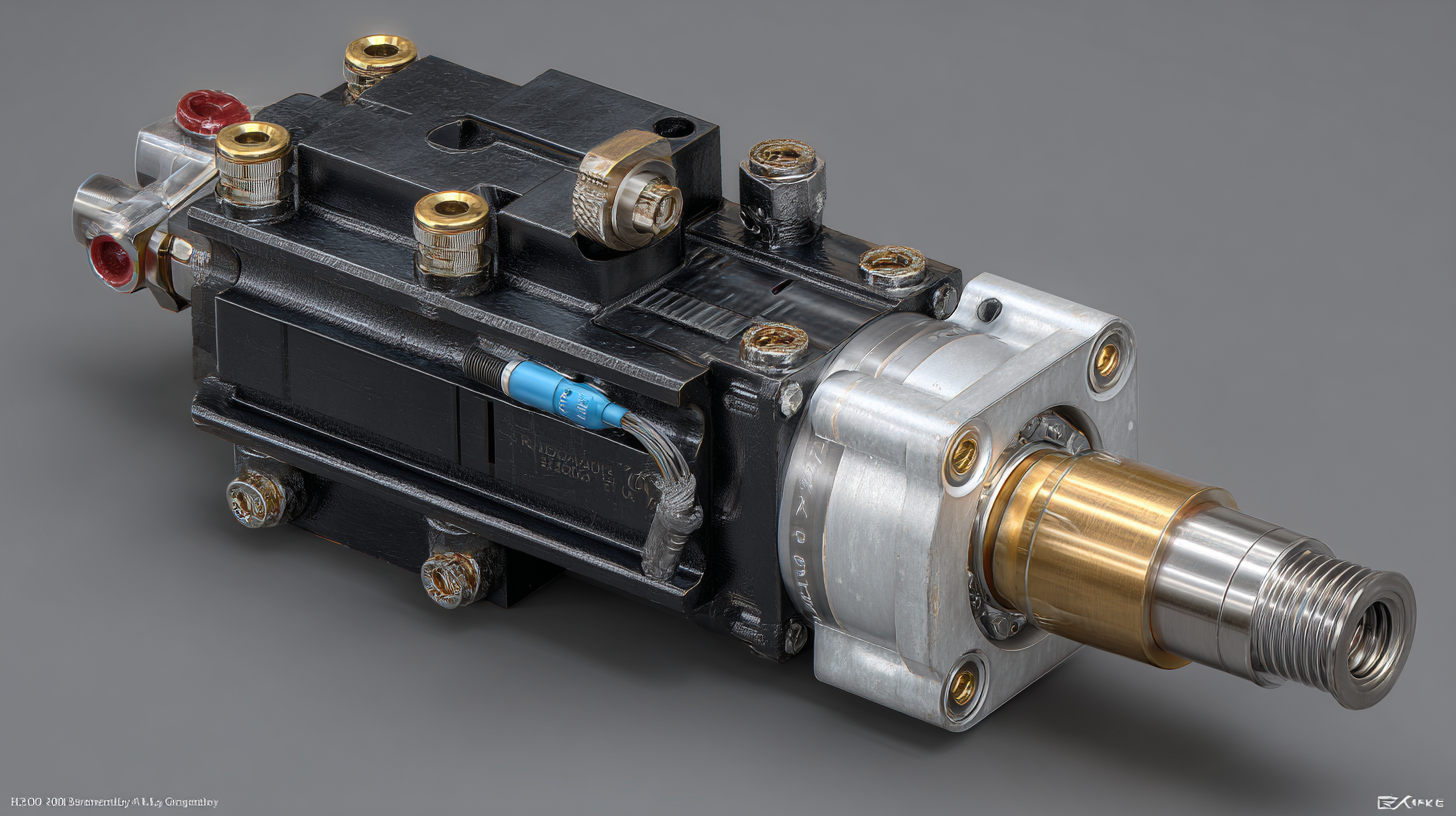

Best Practices for Selecting the Right Hydraulic Pump Motor for Your Needs

Selecting the right hydraulic pump motor is crucial for ensuring efficiency and reliability in various applications. When considering a hydraulic pump motor, it's essential to assess your specific requirements, such as flow rate, pressure, and power. Understanding the application type—be it mobile equipment, industrial machinery, or agricultural tools—can help narrow down suitable options. A thorough evaluation of these factors allows buyers to select a motor that not only meets performance standards but also enhances operational longevity.

Another vital aspect is the compatibility of the hydraulic pump motor with existing systems. Buyers should review the dimensions, mounting configurations, and connection types to avoid costly modifications later. Additionally, consulting with manufacturers or industry experts can provide insights into the best practices regarding motor selection and maintenance. Engaging in regular maintenance checks and utilizing high-quality components will also contribute to the pump motor's efficiency and decrease the likelihood of common issues such as overheating or leaks. By applying these best practices, global buyers can make informed choices that optimize their hydraulic systems.

Hydraulic Pump Motor Performance Analysis

This chart illustrates the efficiency ratings of different hydraulic pump motors based on their horsepower range. Selecting the right motor can significantly impact operational efficiency and long-term maintenance costs.

How to Troubleshoot Hydraulic Pump Motor Issues: A Step-by-Step Guide

Hydraulic pump motors are essential components in various industrial applications, but they can encounter issues that disrupt performance. This step-by-step guide will help you troubleshoot common hydraulic pump motor problems effectively.

Start by observing the motor's operating conditions. Check for any unusual noises or overheating. Make sure to inspect the hydraulic fluid levels and look for leaks in connections. Maintaining proper fluid levels is crucial, as low or dirty hydraulic fluid can lead to reduced efficiency.

**Tip 1:** Always use the recommended hydraulic fluid for your specific motor model to avoid compatibility issues and enhance performance.

If your motor experiences erratic operation or loss of power, examine the electrical connections and components. Ensure all wiring is intact and that there are no signs of corrosion.

**Tip 2:** Regularly check the electrical components and connections, as preventive maintenance can help minimize future issues and downtime.

Finally, if these steps don't resolve the issue, it may be time to consult a professional technician. Their expertise will provide deeper insights into complex problems that may not be immediately evident.

Solving Common Issues with Hydraulic Pump Motors for Global Buyers - How to Troubleshoot Hydraulic Pump Motor Issues: A Step-by-Step Guide

| Issue | Symptoms | Possible Causes | Troubleshooting Steps |

|---|---|---|---|

| Low Pressure | Inadequate power delivery, slow operation | Worn seals, air in system, clogged filters | Check fluid levels, inspect for leaks, replace filters |

| Overheating | High temperature readings, fluid breakdown | Low oil level, excessive load, poor ventilation | Check oil levels, reduce load, improve airflow |

| Unusual Noise | Grinding, whining, or clattering sounds | Worn bearings, low fluid levels | Inspect components, replace fluid, check for contamination |

| Vibration | Excessive shaking of equipment | Misalignment, imbalance, loose connections | Align pump/motor, tighten connections, check mounting |

| Fluid Leakage | Puddles under equipment, visible drips | Damaged seals or hoses | Inspect hoses and seals, replace damaged parts |