- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

Exploring the Versatility and Applications of the Best Hydraulic Pump Motors

In the realm of industrial machinery, the Hydraulic Pump Motor stands out as a pivotal component, renowned for its ability to convert mechanical energy into hydraulic power with remarkable efficiency. As industries continue to evolve, the versatility and applications of hydraulic pump motors have expanded significantly, making them integral to a wide range of operations—from construction and agriculture to manufacturing and automotive. This blog aims to delve into the top strategies for maximizing the performance and reliability of hydraulic pump motors, highlighting their essential role in enhancing productivity and operational effectiveness. By exploring innovative technologies and best practices, we will equip readers with the knowledge to select the right hydraulic pump motor for their specific needs, ensuring optimal performance in various applications. Join us as we uncover the multifaceted benefits and considerations that come with utilizing state-of-the-art hydraulic pump motors in today's dynamic industrial landscape.

Benefits of Using Hydraulic Pump Motors in Industrial Applications

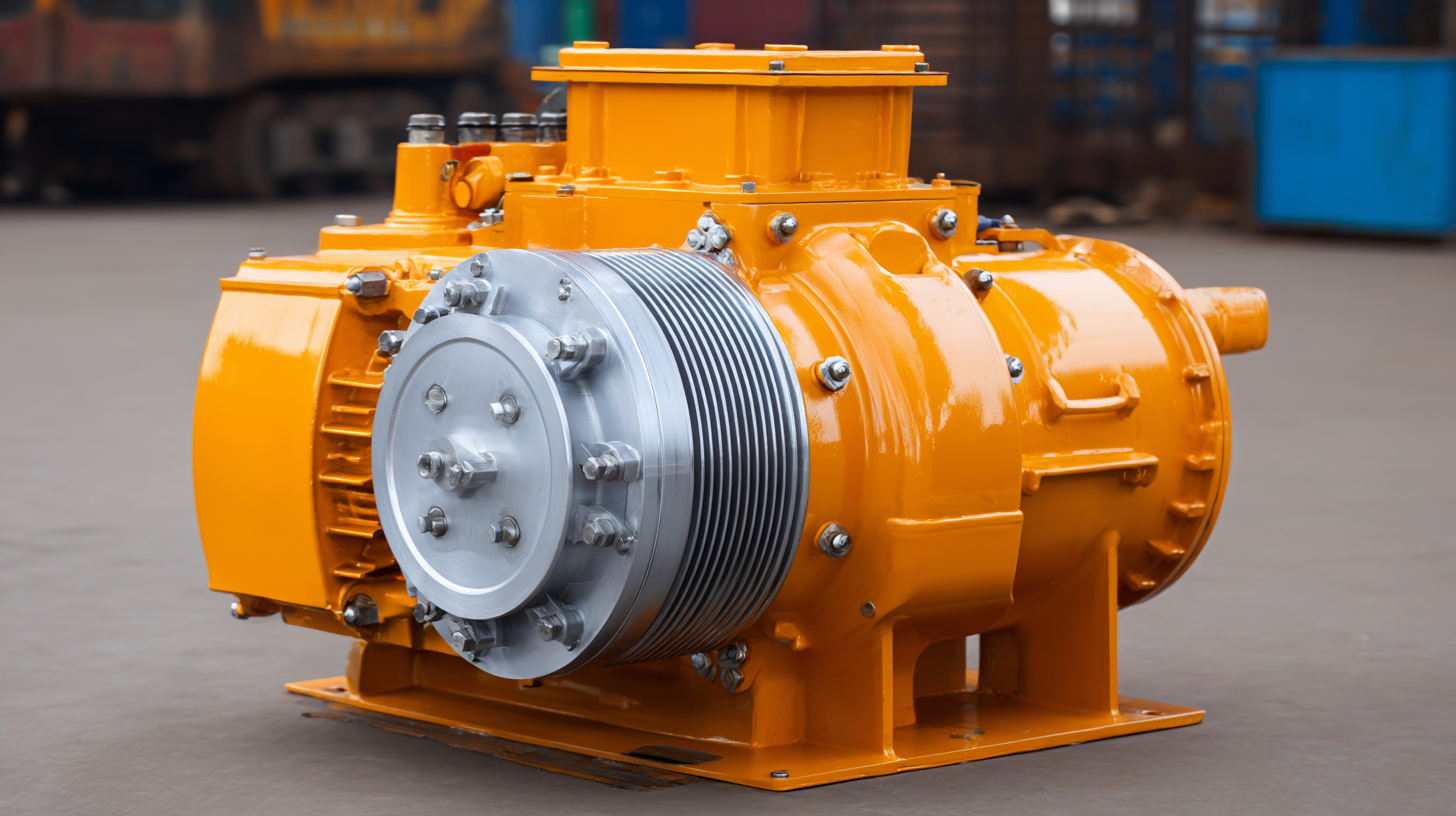

Hydraulic pump motors play a crucial role in numerous industrial applications, providing reliable power and efficiency. One of the primary benefits of using these motors is their ability to deliver high torque at lower speeds, making them ideal for heavy-duty tasks such as construction, manufacturing, and material handling. This characteristic not only enhances performance but also prolongs the lifespan of equipment by reducing wear and tear.

Hydraulic pump motors play a crucial role in numerous industrial applications, providing reliable power and efficiency. One of the primary benefits of using these motors is their ability to deliver high torque at lower speeds, making them ideal for heavy-duty tasks such as construction, manufacturing, and material handling. This characteristic not only enhances performance but also prolongs the lifespan of equipment by reducing wear and tear.

Moreover, hydraulic pump motors offer exceptional versatility, allowing them to be integrated into various systems seamlessly. They can be utilized in a broad range of applications—from hydraulic presses to agricultural machinery. The ability to fine-tune the hydraulic system according to specific needs enables industries to optimize operational efficiency and reduce energy consumption, leading to cost savings. In environments where precision and reliability are paramount, hydraulic pump motors stand out as an indispensable solution, ensuring uninterrupted productivity while maintaining safety standards.

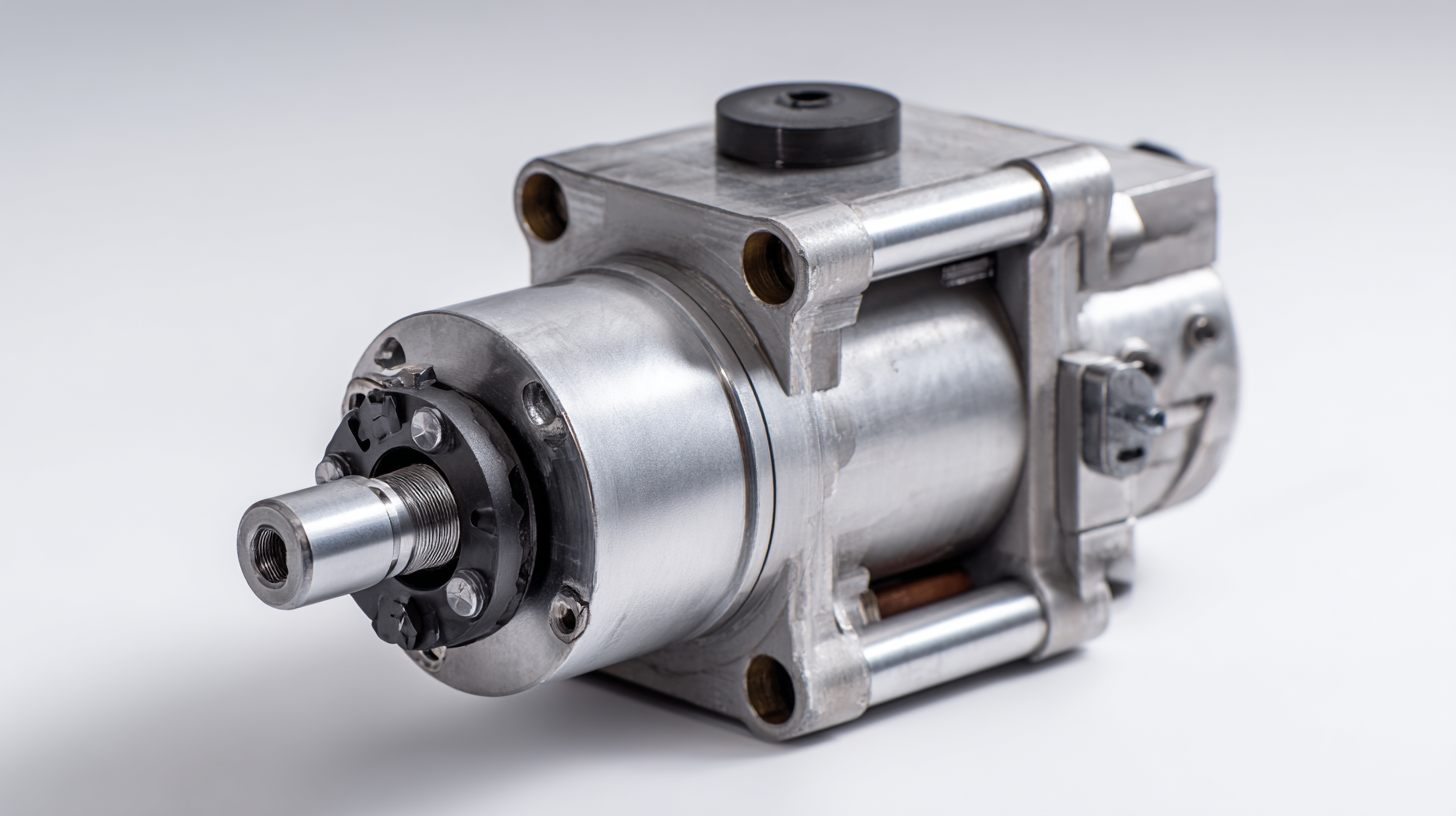

Understanding Different Types of Hydraulic Pump Motors and Their Uses

Hydraulic pump motors play a crucial role in various industrial applications by converting hydraulic energy into mechanical energy. Understanding the different types of hydraulic pump motors—such as gear, vane, and piston motors—can significantly impact equipment performance and efficiency. According to recent industry reports, gear motors are widely used for their simplicity and cost-effectiveness, making them ideal for low-flow applications. In contrast, piston motors are noted for their high efficiency and ability to handle high pressures, suitable for demanding tasks like construction and mining.

When selecting a hydraulic pump motor, consider the application's specific requirements. For instance, if consistent performance under varying loads is a priority, a variable displacement motor may be advantageous. Additionally, integrating a hydraulic accumulator can help manage pressure fluctuations and improve overall system response.

**Tips:** Always evaluate the compatibility of hydraulic pump motors with existing systems to avoid operational issues. Furthermore, regular maintenance and monitoring of performance can prevent unexpected downtimes and extend the lifespan of hydraulic components. Keeping abreast of advancements in motor technology can lead to enhanced productivity and energy savings in the long run.

Key Factors to Consider When Selecting Hydraulic Pump Motors

When selecting hydraulic pump motors, several key factors come into play that can significantly impact performance and efficiency. First and foremost is the type of hydraulic system being used. Understanding whether your application requires a fixed or variable displacement motor is essential, as this influences the motor's speed and torque characteristics. Additionally, the compatibility of the motor with the hydraulic fluid is vital; using the correct viscosity and type can prevent wear and ensure optimal operation.

Another crucial consideration is the operational environment of the hydraulic pump motor. Factors such as temperature extremes, humidity, and exposure to dust or corrosive substances can affect motor performance and longevity. It is important to choose a motor designed to withstand these conditions, ensuring reliability in critical applications. Furthermore, evaluating the power requirements and efficiency ratings helps in selecting a motor that not only meets the specific demands of the task at hand but also optimizes energy usage, reducing operational costs over time.

Exploring the Versatility and Applications of the Best Hydraulic Pump Motors

| Dimension | Value | Application |

|---|---|---|

| Flow Rate (L/min) | 30 | Small Construction Equipment |

| Pressure (bar) | 200 | Industrial Machinery |

| Motor Type | Electric | Automotive Applications |

| Voltage (V) | 400 | Heavy-Duty Equipment |

| Efficiency (%) | 90 | Agricultural Machinery |

Maintenance Tips for Hydraulic Pump Motors to Enhance Longevity

Hydraulic pump motors are integral to various applications in industries such as construction, automotive, and manufacturing. Proper maintenance is critical for enhancing the longevity and performance of these systems. According to a report by the National Fluid Power Association (NFPA), regular maintenance can increase the lifespan of hydraulic components by up to 50%, significantly reducing downtime and operational costs. The primary maintenance strategies include regular fluid analysis, filter changes, and proper system flushing to prevent contamination, which can drastically affect motor efficiency.

Furthermore, adhering to manufacturer guidelines for maintenance routines is essential. A study published in the Journal of Hydraulic Engineering reveals that over 70% of hydraulic system failures are attributed to improper maintenance practices. Ensuring that hydraulic fluid levels are regularly checked and that correct fluid types are used can protect the motor from wear and overheating. Additionally, incorporating vibration analysis and thermal imaging can detect early signs of failure, allowing for proactive repairs that enhance the pump motor's overall reliability and operational efficiency. By investing time in these maintenance tasks, industries can not only extend the life of their hydraulic pump motors but also improve their overall productivity and safety.

Future Trends in Hydraulic Pump Motor Technology and Efficiency

The future landscape of hydraulic pump motors is increasingly intertwined with the advancements in electric motor technology. As sectors prioritize zero carbon emissions and embrace intelligent automation, hydraulic systems are not left behind. According to recent reports, a significant emphasis is being placed on electric drivetrains, opening new avenues for growth within the construction machinery sector. The drive towards electrification could represent a transformative leap, enabling manufacturers to gain competitive advantages in new overseas markets.

With the rise of smart chassis architecture, industry players are shifting towards centralized electronic frameworks that enhance efficiency and performance. This trend is reflected in the growing inclination towards fully electric systems, which promise lower operating costs and improved reliability compared to traditional hydraulic technologies. Moreover, as highlighted by recent developments, organizations are opting to phase out hydraulic systems in favor of direct-drive and quasi-direct drive electric motors, marking a pivotal transition in engineering approaches. These innovations not only promise enhanced efficiency but also align with global sustainability goals, thus reshaping the future of hydraulic pump motor technology.

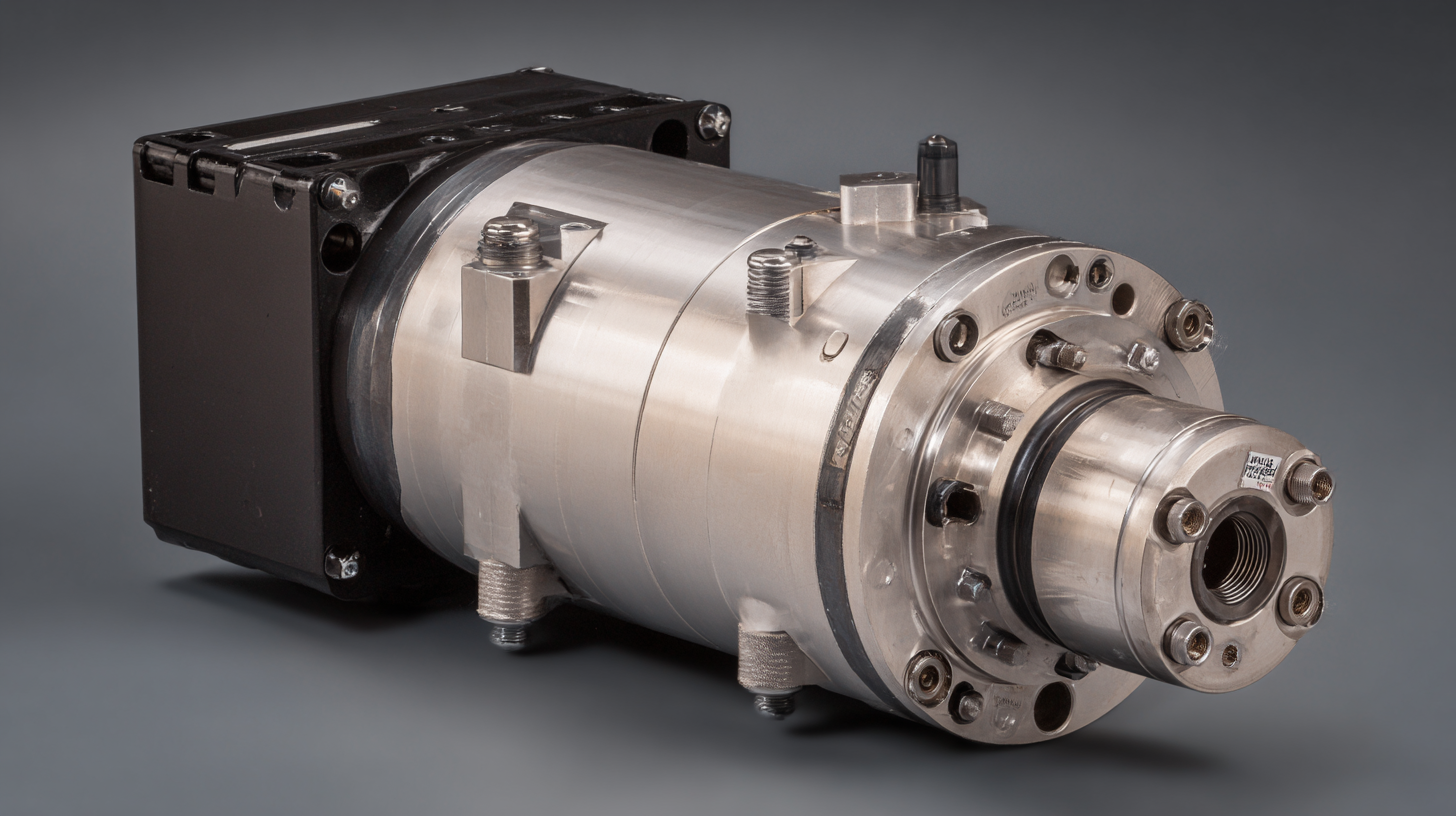

Exploring the Versatility and Applications of Hydraulic Pump Motors

This chart represents key performance metrics of hydraulic pump motors, illustrating their efficiency, torque, power output, and cost. As technology advances, efficiency and power outputs improve, making these motors increasingly versatile in various applications.