- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

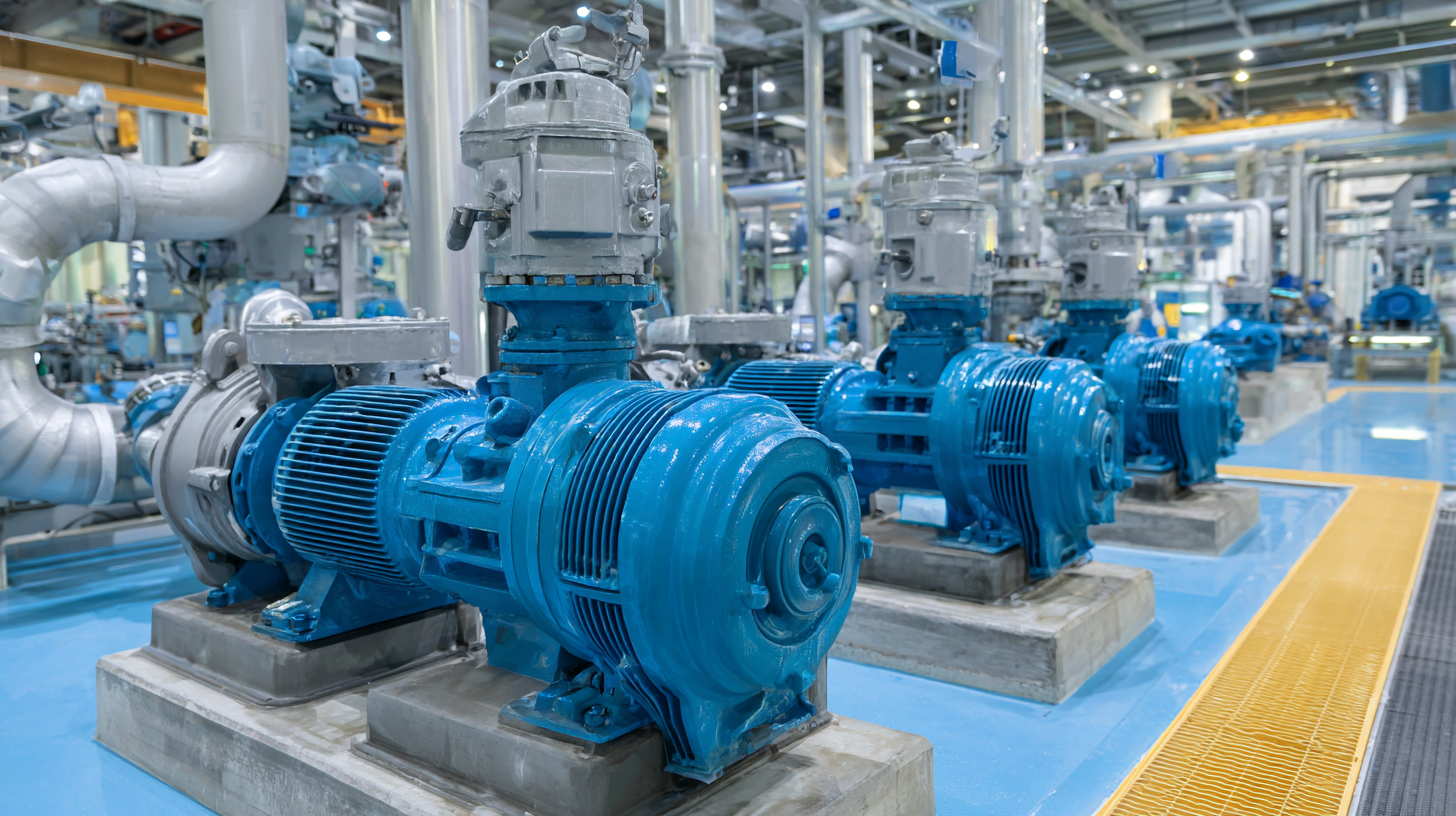

7 Strategies from Best Pump Manufacturers to Boost Your Efficiency

In today's competitive industrial landscape, the efficiency of operations is paramount, particularly for Pump Manufacturers who play a crucial role in various sectors including water treatment, oil and gas, and manufacturing. According to a recent report by the Global Market Insights, the global pump market size is projected to reach approximately $70 billion by 2026, growing at a CAGR of over 5% from 2020. This growth underscores the need for manufacturers to adopt innovative strategies that not only enhance productivity but also minimize operational costs. By leveraging advanced technologies and optimizing their manufacturing processes, leading pump manufacturers can significantly boost efficiency and ensure sustainability in their production lines.

This blog explores seven proven strategies that can help enhance operational workflows, drawing on insights from some of the best manufacturers in the industry.

Innovative Pump Design Techniques to Enhance Operational Efficiency

Innovative pump design techniques are crucial for enhancing operational efficiency in various industries. One of the key strategies adopted by top pump manufacturers is the implementation of advanced materials that reduce wear and tear. By utilizing composites and specialized coatings, manufacturers can create pumps that not only last longer but also operate at lower energy costs. This shift minimizes downtime and maintenance, ultimately contributing to a smoother operational flow.

Innovative pump design techniques are crucial for enhancing operational efficiency in various industries. One of the key strategies adopted by top pump manufacturers is the implementation of advanced materials that reduce wear and tear. By utilizing composites and specialized coatings, manufacturers can create pumps that not only last longer but also operate at lower energy costs. This shift minimizes downtime and maintenance, ultimately contributing to a smoother operational flow.

Another significant aspect of modern pump design is the integration of smart technology. Many leading manufacturers are incorporating IoT-enabled sensors that provide real-time data on pump performance. This technology allows operators to monitor conditions such as flow rates, temperature, and pressure, enabling them to make informed decisions that optimize efficiency. Additionally, predictive maintenance can be facilitated through this data, allowing for proactive interventions before issues arise, which further enhances overall productivity and reliability in operations.

Optimizing Energy Consumption: Tips from Leading Pump Manufacturers

Optimizing energy consumption is crucial for maintaining efficiency in industrial operations, especially when it comes to pump systems. Leading pump manufacturers share valuable insights that can help organizations reduce energy costs while enhancing performance. Here are some effective tips to consider.

First, selecting the right pump type for your specific application is essential. Centrifugal pumps are highly efficient for fluid transfer, while positive displacement pumps excel in applications requiring high pressure. Understanding your system’s requirements ensures optimal performance and minimizes wasted energy.

Additionally, regular maintenance of pumps is critical to ensure they operate at peak efficiency. Scheduling routine inspections can help identify wear and tear before they lead to bigger, more costly problems. Simple practices, such as ensuring that the pump is correctly aligned and that there are no leaks, can significantly enhance energy efficiency and prolong the equipment's lifespan.

Lastly, implementing variable frequency drives (VFDs) can optimize energy consumption further. VFDs adjust the pump motor's speed based on demand, allowing for significant energy savings compared to fixed-speed operations. This kind of adaptive control allows for precise energy use, matching energy output to actual requirements, thus minimizing waste.

Maintenance Best Practices for Prolonged Pump Lifespan

Maintaining pumps effectively is crucial for ensuring their longevity and efficiency. One essential practice is to establish a regular maintenance schedule that includes routine inspections. By monitoring key components such as seals, bearings, and impellers, potential issues can be identified and addressed before they escalate into significant problems. This proactive approach not only extends the lifespan of pumps but also minimizes unexpected downtime, thereby enhancing productivity.

Another vital aspect of pump maintenance is lubrication. Ensuring that pump components are adequately lubricated according to the manufacturer’s specifications can prevent premature wear and tear. Using the correct type of lubricant and following recommended intervals can make a significant difference in operational efficiency and overall equipment health. Furthermore, it's essential to train staff on proper maintenance practices and safety protocols, fostering a culture of responsibility and awareness around pump care. With these best practices in place, operators can maximize pump performance while minimizing the risk of costly repairs or replacements.

Utilizing Automation and IoT for Smart Pump Management

The integration of automation and the Internet of Things (IoT) in pump management is transforming the operational landscape for manufacturers. According to a report by the Global Automation Market in the Pump Industry, the adoption of IoT technologies in industrial settings can lead to efficiency increases of up to 30%. By employing smart sensors and data analytics, manufacturers can monitor pump performance in real time, enabling proactive maintenance and reducing unexpected downtime. This shift towards smart pump management not only optimizes energy consumption but also enhances the lifespan of the equipment.

Moreover, leveraging automation allows for streamlined operations. A recent study by MarketsandMarkets estimated that automated systems in industrial manufacturing could reduce operational costs by nearly 25%. By utilizing advanced analytics, manufacturers can pinpoint inefficiencies and implement corrective measures swiftly. For instance, automated scheduling of maintenance based on predictive insights can ensure optimal pump operation, thus leading to improved productivity and significant cost savings. The combination of IoT and automation is not just a trend; it is a strategic imperative for pump manufacturers aiming to stay competitive in an increasingly complex market.

Efficiency Improvement Strategies in Pump Management

Employee Training Strategies to Maximize Pump Performance

Employee training is crucial for maximizing pump performance in any manufacturing environment. A well-rounded training program equips employees with the knowledge and skills necessary to operate pumps effectively. This includes understanding the fundamentals of pump dynamics, maintenance protocols, and troubleshooting strategies. When employees are trained to recognize the early signs of wear or inefficiency, they can address issues before they escalate, reducing downtime and improving overall operational efficiency.

Additionally, fostering a culture of continuous learning empowers employees to stay updated with the latest technologies and practices in pump manufacturing. This can involve workshops, online courses, or hands-on training sessions led by experienced colleagues or industry experts. Implementing peer mentoring programs can also enhance learning, as seasoned employees can share their insights and best practices with newer team members. By investing in employee training, manufacturers not only boost pump performance but also cultivate a more knowledgeable and engaged workforce, ultimately driving productivity and innovation.