- Ambawadi, Ahmedabad, Gujarat

- View Mobile Number

10 Top High Pressure Pump Innovations Transforming Industrial Efficiency in 2023

In the ever-evolving landscape of industrial technology, high pressure pumps stand out as crucial components driving efficiency and productivity across various sectors. As we enter 2023, numerous innovations in high pressure pump design and functionality are reshaping operational capabilities. This blog will explore the top ten advancements that are pushing the boundaries of what is possible in industrial settings, focusing on how these innovations are not only enhancing performance but also contributing to sustainability and cost-effectiveness.

From improved materials that extend service life to smart technologies that optimize operations, these high pressure pump breakthroughs are set to transform the way industries approach their processes. By examining these cutting-edge innovations, we provide a comprehensive checklist for organizations aiming to harness the full potential of high pressure pumps in their quest for enhanced industrial efficiency.

From improved materials that extend service life to smart technologies that optimize operations, these high pressure pump breakthroughs are set to transform the way industries approach their processes. By examining these cutting-edge innovations, we provide a comprehensive checklist for organizations aiming to harness the full potential of high pressure pumps in their quest for enhanced industrial efficiency.

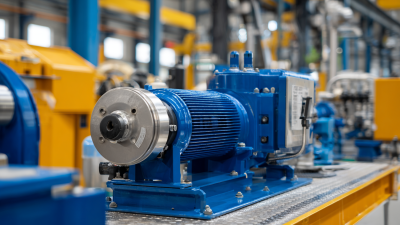

Revolutionary Design Features in High Pressure Pumps for Enhanced Performance

In 2023, the landscape of high pressure pumps is witnessing groundbreaking innovations that significantly enhance operational efficiency across various industries. One notable design feature is the integration of advanced materials that can withstand extreme pressures and temperatures, ensuring durability and longevity. These materials not only reduce wear and tear but also improve the overall reliability of the pumps, allowing industries to minimize downtime and maintenance costs.

In 2023, the landscape of high pressure pumps is witnessing groundbreaking innovations that significantly enhance operational efficiency across various industries. One notable design feature is the integration of advanced materials that can withstand extreme pressures and temperatures, ensuring durability and longevity. These materials not only reduce wear and tear but also improve the overall reliability of the pumps, allowing industries to minimize downtime and maintenance costs.

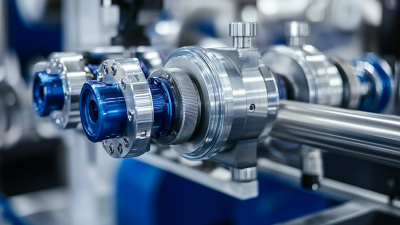

Another revolutionary aspect is the implementation of smart technology, which includes IoT connectivity and real-time monitoring systems. These features enable operators to collect and analyze data on pump performance and energy consumption. By harnessing this information, companies can optimize their processes, reduce energy usage, and prevent potential failures before they occur. Additionally, new designs often incorporate modular components, which facilitate easier upgrades and maintenance, further enhancing the pumps' performance and adaptability to varying industrial demands.

The Role of Smart Technology in Modern High Pressure Pump Systems

In 2023, the integration of smart technology into high pressure pump systems is reshaping industrial efficiency across various sectors. According to a report by MarketsandMarkets, the global smart pumps market is expected to grow from $6.6 billion in 2021 to $14.4 billion by 2026, at a CAGR of 16.7%. This surge is driven by the need for improved energy efficiency and operational reliability, particularly in manufacturing and chemical processing environments.

One of the most significant innovations is the incorporation of IoT and AI capabilities in high pressure pumps. These advancements enable real-time monitoring and predictive maintenance, which can reduce downtime by up to 30%, as highlighted in a study by Frost & Sullivan. Smart sensors are now deployed to gather data on pump performance, allowing operators to anticipate failures before they occur and optimize their operations. This not only leads to cost savings but also enhances sustainability by minimizing energy consumption and waste.

Furthermore, advanced data analytics is enabling manufacturers to tailor their pump systems to specific applications, improving compatibility and performance. With the implementation of machine learning algorithms, systems can adjust parameters automatically, resulting in enhanced precision and efficiency. As industries continue to embrace these high-tech solutions, the future of high pressure pumps seems poised for unprecedented improvements in operational efficiency and reliability.

10 Top High Pressure Pump Innovations Transforming Industrial Efficiency in 2023 - The Role of Smart Technology in Modern High Pressure Pump Systems

| Innovation | Description | Efficiency Gain (%) | Smart Technology Integration | Year Implemented |

|---|---|---|---|---|

| Advanced VFD Systems | Variable Frequency Drives optimize energy use and provide precise control. | 25 | Yes | 2023 |

| IoT Connectivity | Real-time monitoring and diagnostics using IoT for predictive maintenance. | 30 | Yes | 2023 |

| Smart Sensors | Sensors for monitoring pressure and flow rates, enhancing operation reliability. | 15 | Yes | 2023 |

| Energy Recovery Devices | Devices that harness wasted energy to improve overall efficiency. | 20 | No | 2023 |

| Predictive Analytics | Using data algorithms for optimizing performance and maintenance schedules. | 28 | Yes | 2023 |

| Remote Control Systems | Allows operators to control pumps remotely, reducing downtime. | 18 | Yes | 2023 |

| Automated Pressure Controls | Systems adjust pressure settings automatically based on operational demand. | 22 | Yes | 2023 |

| Inline Leak Detection | Immediate identification of leaks to minimize losses and hazards. | 15 | Yes | 2023 |

| Modular Pump Designs | Easier maintenance and scalability through modular components. | 19 | No | 2023 |

| Hybrid Power Solutions | Combines traditional and renewable power sources for greater reliability. | 30 | No | 2023 |

Sustainable Innovations: Eco-Friendly High Pressure Pump Solutions

As industries strive for greater efficiency while minimizing their environmental impact, the rise of eco-friendly high-pressure pump solutions has gained significant momentum in 2023. These innovations not only enhance performance but also focus on sustainability, making them crucial for modern industrial practices. By utilizing advanced materials and energy-efficient designs, these pumps reduce energy consumption and lower emissions, aligning with global efforts toward greener operations.

To maximize the benefits of these sustainable innovations, consider implementing regular maintenance schedules. Proper upkeep ensures optimal performance and longevity of high-pressure pumps, reducing the need for replacements and limiting waste. Additionally, investing in training for staff on eco-friendly practices can lead to significant improvements in operational efficiency while fostering a culture of sustainability within the workplace.

Another tip for embracing eco-friendly high-pressure pumps is to evaluate the energy sources used to power them. Opt for renewable energy options, such as solar or wind, to further decrease carbon footprints. This combination of innovative technology and conscious energy practices not only enhances industrial output but also contributes to a healthier planet.

Safety Enhancements in High Pressure Pumps: A 2023 Perspective

In 2023, the high-pressure pump industry has seen significant advancements that prioritize safety enhancements, making these machines not only more efficient but also safer for operators and the environment. One of the most notable innovations is the integration of

real-time monitoring systems, which allow for constant oversight of pump performance and operational parameters. These systems can detect anomalies and alert operators to potential failures before they escalate, thereby reducing risks and minimizing downtime.

Additionally, manufacturers are incorporating advanced materials and designs that improve the structural integrity of high-pressure pumps. By utilizing corrosion-resistant materials and implementing fail-safe mechanisms, these pumps can withstand extreme conditions without compromising safety. Enhanced sealing technologies further prevent leaks, ensuring that hazardous fluids are contained and reducing the likelihood of accidents. As industries increasingly prioritize safety, these innovations not only comply with stringent regulations but also foster a culture of careful operation and maintenance.

Comparative Analysis: Traditional vs. Advanced High Pressure Pump Technologies

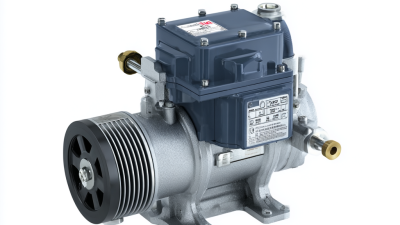

In the realm of industrial operations, the evolution of high pressure pump technologies has been nothing short of revolutionary. Traditional high pressure pumps, while robust and reliable, often lack the efficiency and flexibility required in today’s competitive landscape. These conventional systems are typically characterized by rigid structures and limited automation capabilities, which can lead to increased operational costs and reduced energy efficiency. Furthermore, their maintenance and, at times, the inefficiency in handling varying fluid dynamics can hinder productivity in the long run.

In contrast, advanced high pressure pump technologies incorporate state-of-the-art innovations such as smart sensors, AI-driven control systems, and modular designs. These modern pumps not only optimize performance with real-time monitoring but also adapt seamlessly to changing operational conditions. For instance, variable frequency drives allow for precise flow regulation, significantly reducing energy consumed during low-demand periods. This adaptability not only enhances efficiency but also extends the lifespan of the equipment. Together, these innovations create a paradigm shift in how industries approach fluid handling, ultimately fostering greater resilience and competitiveness in the marketplace.

Related Posts

-

7 Reasons Why the Best High Pressure Pump is Essential for Your Industrial Operations

-

Exploring the Versatility of High Pressure Pumps Across Different Industries and Their Unique Benefits

-

Global Buyers Choose Chinese Made Pressure Pumps for Superior Quality Upgrades

-

Discover Cutting-Edge Hydraulic Control Valve Innovations at the Upcoming 138th Canton Fair!

-

Exploring Alternatives to Best Hydraulic Motors for Global Sourcing Opportunities

-

Top 10 Hydraulic Manufacturers from China at the 137th Canton Fair